Our R&D strength is rooted in technological accumulation and innovative breakthroughs. Relying on professional R&D laboratories, we focus on two main directions: materials research and structural innovation. On the materials side, we continuously iterate on the formulation of special materials such as food-grade silicone and high/low temperature resistant, anti-aging plastics to meet the stringent standards of multiple fields, including medical, industrial, and consumer electronics. On the structural side, we overcome technical challenges such as waterproofing, dustproofing, shock absorption, and multi-device compatibility to achieve optimal product performance. Furthermore, our seamless "R&D-prototyping-mass production" model can shorten the development cycle of customized products by 30%, allowing for rapid response to your market needs.

From initial concept sketches to finished product delivery, from single-product customization to comprehensive series solutions, we are driven by design and R&D to safeguard your products.

• Mold Manufacturing

Precision Customization | Unlocking New Heights in Silicone and Plastic Product Customization

In the wave of customization demands for electronic terminals and industrial components, design capabilities and mold manufacturing expertise are the core lifelines determining product quality and delivery efficiency.

As an integrated manufacturer and trader of silicone and plastic product customization, we have cultivated deep expertise in the industry for many years. With "Design-Driven Innovation, Molds forging Quality" as our core competitiveness, we provide global B2B clients with one-stop customization solutions from concept to finished product.

Weijiamei's Own Mold Production Workshop

Our design team possesses a deep understanding of the functional requirements and market trends of products across various industries, with particular expertise in the structural design and aesthetic optimization of products such as handheld terminal protective cases and plastic casings for electronic products. From achieving waterproof, drop-proof, and wear-resistant functionality, to ensuring an ergonomic grip experience, and finally to a visual presentation that aligns with the brand's image, we use meticulous design to transform clients' creative concepts into feasible product solutions, effectively mitigating mass production risks.

Mold manufacturing is one of our core strengths. We are equipped with professional mold processing equipment and a senior technical team, strictly controlling precision throughout the entire process, from mold design, CNC machining, EDM machining to trial molding and optimization. Targeting the characteristics of silicone and plastic materials, we optimize the mold cooling system and demolding structure to ensure that product dimensional errors are controlled within a minimal range, resulting in high surface finish and strong mass production stability. Our efficient mold development capabilities can significantly shorten product delivery cycles, helping customers seize market opportunities.

From precise implementation of product design to meticulous mold manufacturing, we are always customer-oriented, empowering B-end clients with our professional capabilities. Whether it's custom-designed, highly complex structural components or large-scale standardized production, we can provide cost-effective customized solutions.

Choosing us means more than just customizing products; it's customizing your core competitiveness.

• Quality Assurance and Laboratory Equipment

Quality as the Foundation, Crafting Peace of Mind – Our Unwavering Commitment to Quality in Silicone and Plastic Products

Currently, silicone and plastic products are widely used in various sectors of daily life and industry. Quality directly impacts user experience, safety, and corporate reputation. For related manufacturers, quality control is the core principle throughout the entire process and the foundation for survival in the market.

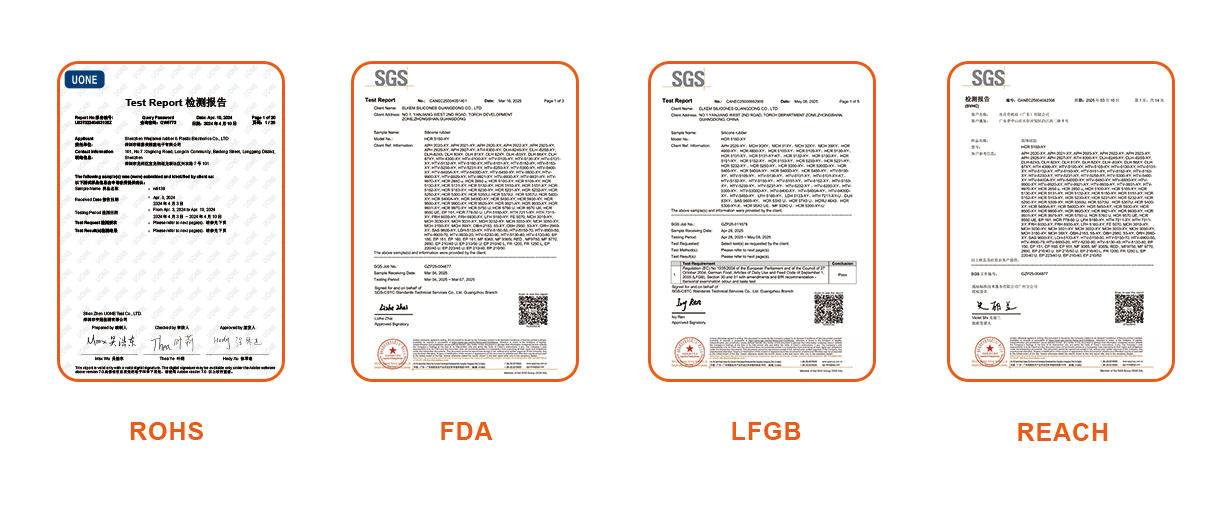

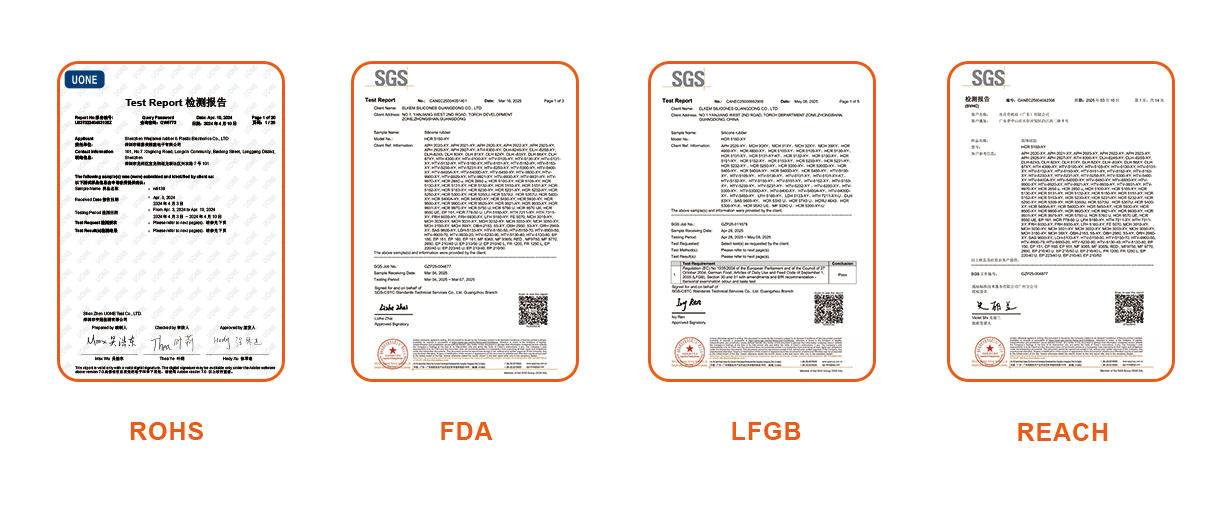

We have already passed quality management system certification, environmental certification, and occupational health certification.

All of Weijiamei's products undergo rigorous quality inspection, and to date, over 100 million qualified products have been delivered to customers.

Quality control begins at the source

We carefully select food-grade silicone and high-purity plastic raw materials that meet international environmental standards. Before warehousing, we conduct comprehensive testing on key parameters such as hardness, tensile strength, and environmental indicators. Only after meeting the standards can production begin. All raw materials used have passed relevant certifications.

The production process is the core of quality control

We have built standardized workshops and introduced automated equipment and precision instruments to accurately control all processes, including mixing, injection molding, and vulcanization. Key parameters are monitored in real time at each stage, and molded products undergo both manual and machine screening to ensure accurate dimensions and flawless appearance.

Finished product inspection is the final step in quality control. We have established a multi-dimensional testing system to specifically test the fit and abrasion resistance of silicone protective cases, the pressure resistance and non-toxicity of plastic products, and re-examine environmental indicators. Qualified products are accompanied by quality labels, fulfilling our commitment to consumer responsibility.

Continuous optimization of the quality system is key to improvementWe have established a full-process traceability system to quickly locate and rectify problems; we regularly conduct quality training to create a company-wide quality control atmosphere; and we closely follow industry standards and market feedback to optimize processes and maintain leading quality.

In market competition, quality is the core competitiveness. We adhere to the bottom line of quality, integrating quality control into every detail, all to create safer and higher-quality products, fulfilling our responsibility with quality, and building our brand with craftsmanship.