All-Round Physical Defense: Soft, elastic silicone acts as a cushion, minimizing impact damage from drops or collisions for devices like POS terminals, PDAs, and handheld terminals. This helps prevent scratches, screen cracks, and internal component failure.

For businesses relying on handheld terminals—such as POS systems, warehousing, logistics, supermarket inventory, outdoor checks, and specialized equipment handling—device reliability directly affects operational quality. As a low-cost accessory, silicone protective cases deliver value well beyond basic protection. They support businesses across three key dimensions: cost savings, efficiency improvement, and compliance assurance, making them a practical tool for reducing costs, boosting efficiency, and mitigating risks.

Handheld terminals involve high procurement and maintenance costs. Daily drops, collisions, dust, and environmental wear often lead to frequent damage, trapping businesses in a costly cycle of “repair–damage–repair.” Silicone cases address this at the source through holistic protection, delivering tangible savings.

Impact Resistance: Highly elastic silicone cushions against drops and collisions. Real-world tests show it can reduce screen breakage and body deformation by over 80%, cutting repeated expenses on parts and labor.

Longevity Extension: UV resistance, splash protection, and dustproofing slow casing aging and internal wear, extending device lifespan by roughly 30% and deferring upgrade costs.

Easy Maintenance: The dirt-resistant, easy-to-clean surface lowers daily cleaning efforts and material costs, shifting focus from post-failure repair to preventive, low-cost care.

By adopting silicone cases, companies move from reactive spending to lifecycle cost control—achieving predictable expenses and sustained device performance.

3. Success Cases: Typical Application Scenarios

3.1 POS Machine Silicone Protective Cover

In high-frequency transaction scenarios such as retail, catering, and supermarkets, POS machines are a powerful revenue-generating tool for merchants. However, frequent movement, accidental bumps, and oil stains cause rapid wear and tear, high maintenance costs, and a significantly reduced lifespan.

Common POS machine protective cases either don't fit properly, making installation and removal difficult, lack sufficient protection for complex scenarios, or don't match the brand image.

Our tailored silicone covers address four key pain points for B2B clients:

Precise Fit: Designed to match your POS model exactly, ensuring a snug fit without interfering with scanning, card reading, or button operation. Easy and quick to install.

Enhanced Protection: Made from high-toughness silicone, the cover resists abrasion, scratches, drops, and impacts. It guards against daily bumps, oils, and dust—extending device life and significantly lowering repair and replacement costs.

In logistics scanning, industrial inspection, or retail inventory, PDAs often face screen breakage, oil seepage, and button failure. Our integrated manufacturing solution delivers tougher, tailored silicone cases to keep your equipment running smoothly and durably.

Drop-Resistant and Durable: Thickened corners and an airbag cushioning design, passing drop tests to effectively prevent damage from falls from heights.

Stain-Resistant and Easy to Clean: An oil-resistant coating on the surface allows for easy wiping away of dust and oil stains, suitable for complex environments such as cold chain facilities and workshops.

Smooth and Secure Fit: A fully enclosed design ensures a secure fit, with clear button feedback and smooth, lag-free scanning and operation.

Flexible Customization: Supports personalized designs for colors, logos, lanyard holes, and anti-slip textures, balancing practicality and brand recognition.

Directly Addressing the Core Pain Points of Customization

Inadequate Performance: Silicone is prone to deformation and odor release under high temperatures and direct sunlight, and its anti-slip and anti-tipping effects diminish rapidly.

Low Customization Efficiency: Traditional suppliers have long mold-making cycles, resulting in high costs for small-batch customization and difficulty in keeping pace with new car development.

High Compliance Risks: Materials fail to meet environmental and weather resistance standards, making it impossible to pass the stringent certifications of the automotive industry.

3.3.1 Silicone Center Console Storage Pouch

Technical Challenges: Balancing space utilization with installation compatibility, avoiding obstruction of original vehicle function buttons, and resolving noise issues on bumpy roads.

Technical Challenges: Heat is concentrated during wireless charging, requiring a balance between anti-slip performance and efficient heat dissipation, while avoiding interference with the charging signal.

Our Solution: Incorporating a thermally conductive silicone formula, the surface features a honeycomb-like anti-slip texture. This ensures 360° anti-slip fixation while improving heat dissipation efficiency by 40%. It has passed electromagnetic compatibility testing and does not affect wireless charging power.

Technical Challenges: The cup holder must be compatible with different sizes of cups/bottles, prevent tipping during rapid acceleration and sharp turns, and withstand high and low temperatures.

Our Solution: Utilizing a partitioned, flexible structural design, combined with a wide-temperature silicone material resistant to -40℃ to 150℃, and with densely packed anti-slip particles on the inner wall, this design ensures stable fixation for round and square bottles. It is RoHS and IATF 16949 certified.

Customized Protection: Action Camera Silicone Cases Precisely Match B2B Needs

Action cameras are used in complex environments, and generic protective cases often fail to fit the structure and protection requirements of different models. Our customized services solve this pain point for B2B clients. As a source factory specializing in customized silicone products, we leverage our end-to-end capabilities to provide a unique protective solution for every action camera.

Addressing the differences in body curvature, button layout, and interface positions among various brands of action cameras, we utilize precise 3D modeling based on blueprints and CNC precision molding technology to achieve a seamless fit. From millimeter-level positioning of the lens aperture to tactile optimization of the button area, every detail is matched to the characteristics of the model, ensuring both operational sensitivity and compatibility with accessories such as lanyards and tripods. We support customization for all types of action cameras, from mini portable models to professional outdoor models, and have already provided adaptation solutions for many well-known brands.

We specialize in custom silicone products and design high-compatibility protective cases for B2B clients:

Precise Fit, Uninterrupted Operation: Utilizing 3D modeling and precision mold-making, our cases perfectly match the device contours, ensuring accurate alignment of buttons, ports, and probes without hindering operation or signal transmission.

4. Core Customization Capabilities | Integrated Solutions

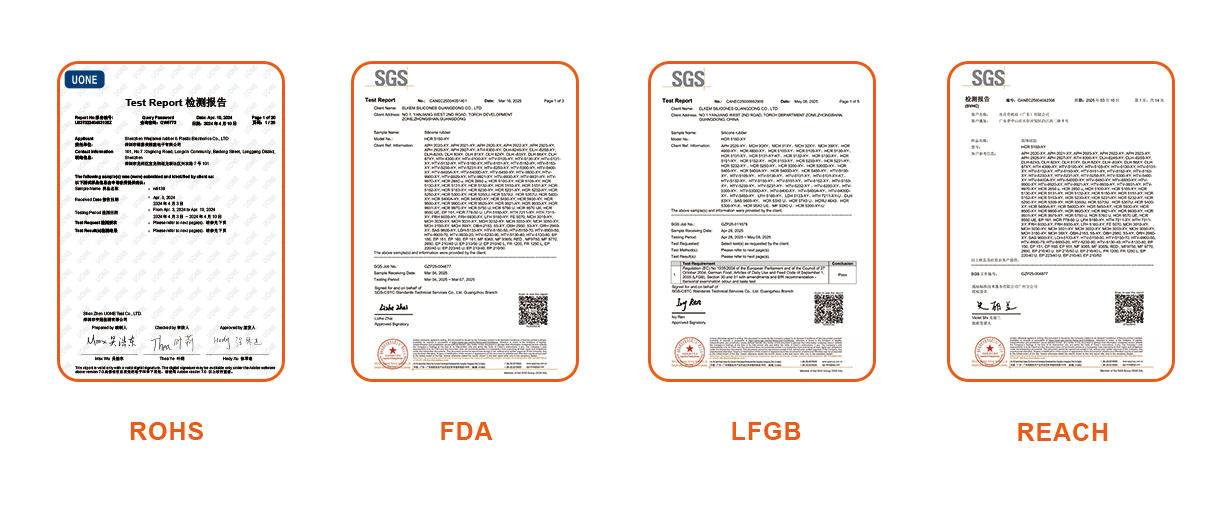

Weijiamei, with its professional expertise in the silicone and plastic industries, has obtained IATF16949 Quality Management System Certification, Environmental Management System Certification, and Occupational Health and Safety Certification, ensuring compliance and reliability throughout the entire production process. We are committed to using raw materials that meet international environmental standards, providing you with safe and eco-friendly product assurance.

Hard Strengths Supporting Customized Services

Technical Expertise: Holds over 20 related patents, driving continuous innovation in craftsmanship.

Smart Manufacturing: Implements an automated production system, achieving full-process control from material mixing and precision molding to finished product inspection.

Accurate Delivery: Owns an independent mold workshop and a Class 100,000 cleanroom, equipped with complete production facilities to offer one-stop service from design, mold development, and sampling to mass production.

Rapid Response: Provides samples within 5–7 days and completes delivery within 15 days. Small-batch orders are flexibly accommodated, with fast mold development supported in just 7 days.

Strict Quality Control: Product dimensional tolerance is controlled within ±0.1mm. Materials comply with food-grade safety certification, featuring aging resistance and odor-free properties.

We offer end-to-end customized services from R&D design, mold manufacturing to production and delivery, implementing strict quality control throughout the entire process to fully support your bulk procurement needs. With dedicated one-on-one service following up from requirement communication to solution implementation, we leverage our professional strength to build a solid protective barrier for your equipment—effortlessly solving your procurement challenges.