The production of silicone buttons goes through many processes from design to final packaging. Among them, some of them need to be covered with double-sided tape in order to be applied to the product. So, how does this process wjm do it? Through the video, you can see that even a small button requires so many people to work together. First, we need to brush the buttons with silicone treatment agent and let it sit for 15 minutes. This is mainly to change the properties of the silicone surface, making it more sticky and convenient for sticking double-sided tape. Then each person is responsible for a part and put on double-sided tape. Thus, the process is completed.

Basic Information

-

Year Established

2002

-

Business Type

Factory

-

Country / Region

No 7,Xingnong Road,Baolong Street, Longgang District, Shenzhen China

-

Main Industry

Mobile Phone & Accessories

-

Main Products

Silicone rubber products; plastic products; mobile phone silicone cases; all kinds of protective covers; digital accessories

-

Enterprise Legal Person

Zhong Xiaoping

-

Total Employees

101~200 people

-

Annual Output Value

--

-

Export Market

European Union,Middle East,Eastern Europe,Latin America,Africa,Oceania,Hong Kong and Macao and Taiwan,Japan,Southeast Asia,America,Others

-

Cooperated Customers

TESCO; BUSHNELL、CASE-MATE、HAMA

Company Profile

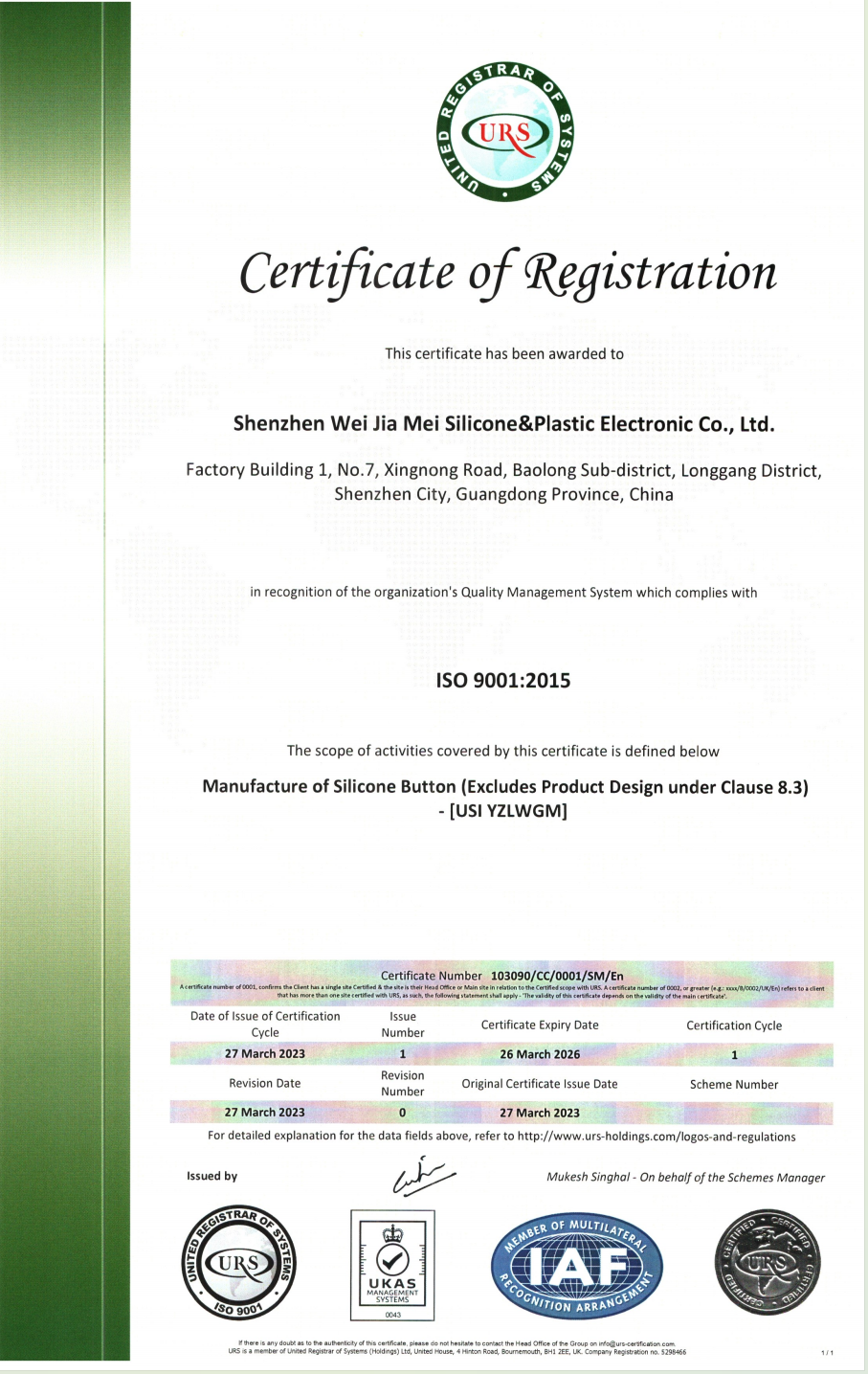

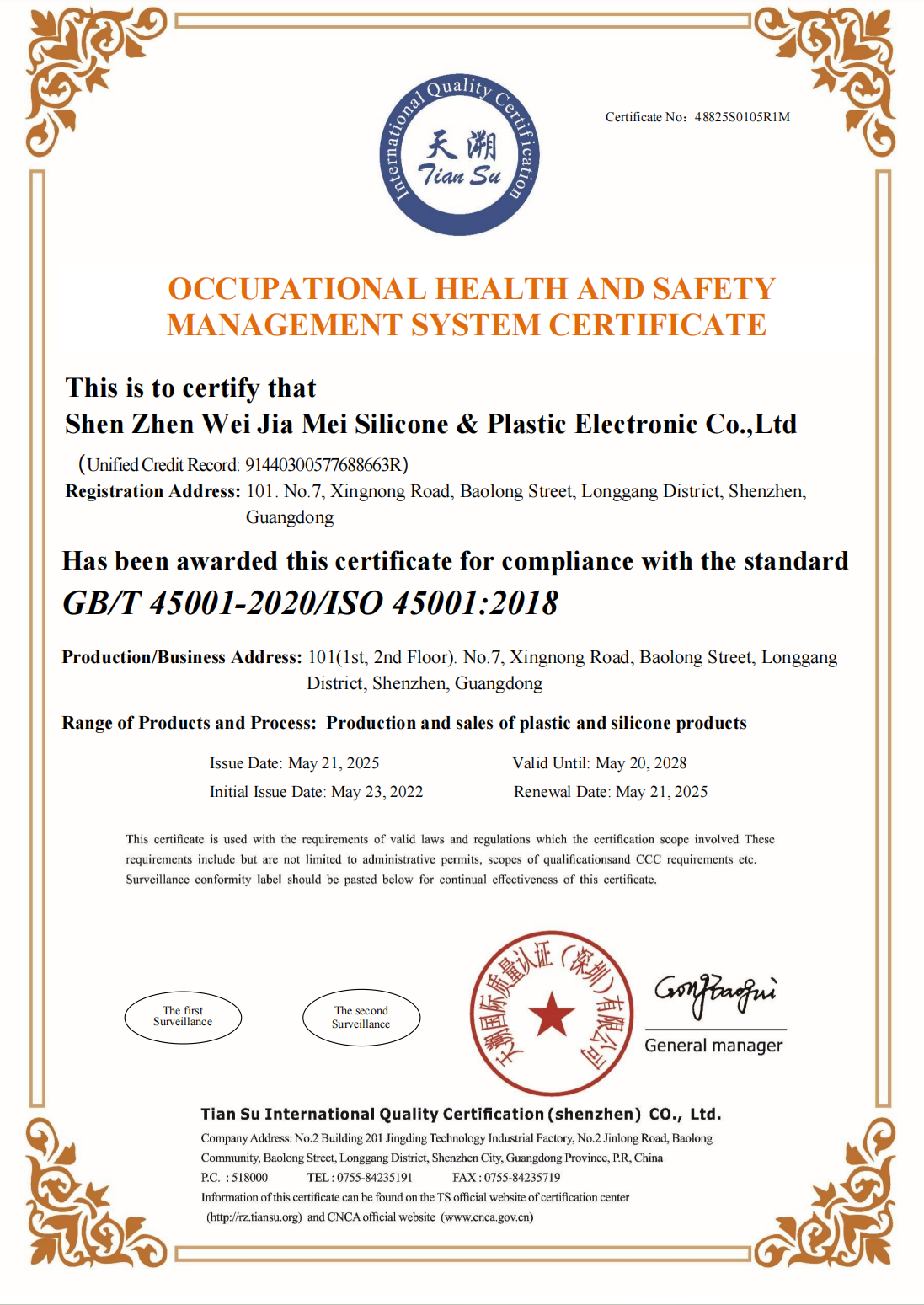

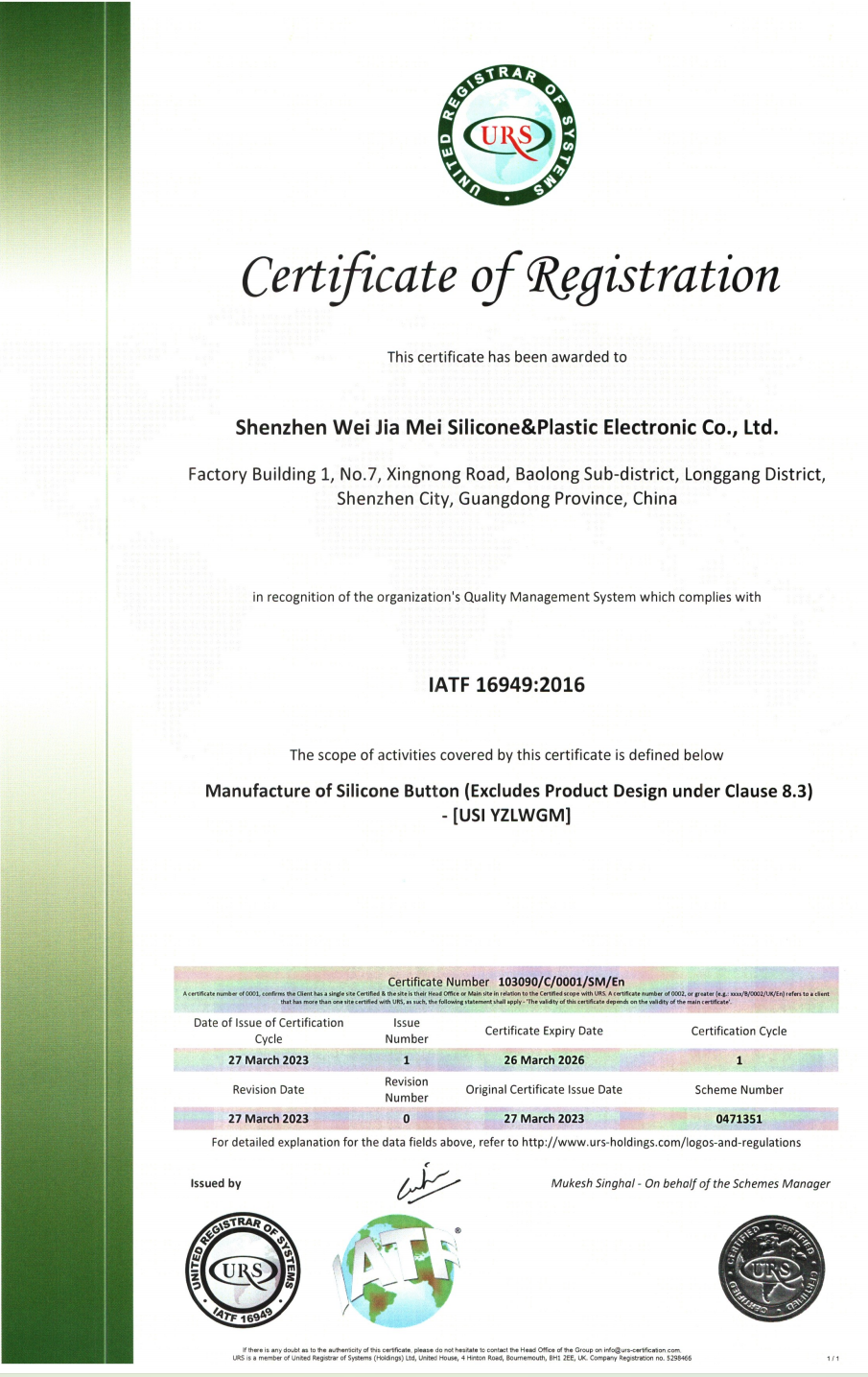

Shenzhen WJM Silicone & Plastic Electronic Co., Ltd. is located in Baolong Street, Longgang District, Shenzhen. The main business has two major sectors, mobile phone accessories silicone plastic products and auto parts supply series, Weijiamei was established in 2002, covers an area of 12,000 square meters with more than 200 employees. The factory has passed ISO9001 quality certification, ISO14001 factory environmental certification,

ITAF16949 automotive system certification, OHSAS18001 occupational health certification. We have been adhering to the firm belief of "only doing first, not doing second!" and have established a good reputation in the industry! We have strong engineering research and development capabilities and product production capabilities, such as precision injection molding workshop, silicone product workshop, precision mold workshop, auto parts production workshop, modern quality packaging production line.

At the same time, a group of enterprise management personnel, engineering and technical personnel and on-site operators with rich industry experience were brought together. The main customers are world-renowned companies from Europe and America: TESSCO; BUSHNELL, CASE-MATE, HAMA, etc. Main business: Mobile phone accessories: mobile phone case, tablet case, POS case, camera case, all kinds of silicone plastic products.

Company Video

Certifications

ISO 9001

Issue by:URS Ltd.

ISO 14001

Issue by:Tian Su International Quality Certification(shenzhen)CO., Ltd.

ISO 45001

Issue by:Tian Su International Quality Certification(shenzhen) CO. Ltd

IATF 16949

Issue by:URS Ltd.