We will show you our best quality control and inspection team during the production process. Click on the video and the page to watch more content and learn more. If you like, remember to subscribe to this video!

Mainly engaged in mobile phone accessories silicone plastic products and auto parts supply series two major sectors. The factory has passed ISO9001 quality certification, ISO14001 factory environmental certification,

ITAF16949 automobile system certification, OHSAS18001 occupational health certification. We have always been adhering to the firm belief of "being only the first, not the second"! And established a good reputation in the industry! We have strong engineering research and development capabilities and product production capabilities and modern boutique packaging production lines. A group of enterprise management personnel, engineering and technical personnel and on-site operators with rich industry experience have been gathered

Partner:

TESCO; BUSHNELL,

CASE-MATE, HAMA, etc.

Production:

Mobile phone case, tablet computer case

POS case, camera case

Various silicone plastic products.

Our QC will check every process to ensure that all products meet AQL standards before packaging. 100% inspection of the production line. If the received item is acceptable, the QC inspector will put a PASSED label on the item. From production to delivery, the products go through various quality inspections, and the product quality is guaranteed.

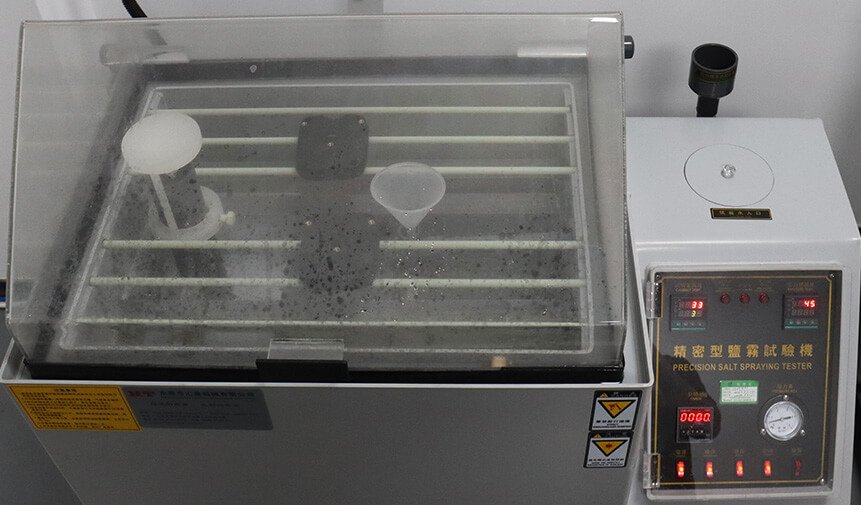

There are 6 different types of testing machines, including UV accelerated aging testing machine, precision salt spray testing machine, constant temperature and humidity box. We will test the samples after sampling the samples. Ensure that all details and functions are correct.

Quality inspection not only relies on the use of advanced digital equipment, but also on well-trained personnel with many years of experience. Our quality department holds a weekly meeting to discuss product quality, content quality standards, quality processes, the use of quality inspection tools, and how to better serve customers.

Extensive verification of incoming materials and every detail required. Provide all referenced manufacturing document designs. Manual inspection of product data and functions. The inspection machine inspects product features and details. Raw materials are inspected before production to eliminate defective products

Committed to continuously improving our industry-leading quality control and quality assurance processes, our silicone products have passed the comprehensive certifications of ISO9001, ISO14001, IATF16949, SGS, ROHS, REACH, and FDA.

Test the adaptability of silica gel products, parts, and materials in storage, transportation, and use under -40 degrees-150 degrees, high and low temperature alternating humid and hot environments; test products in high and low-temperature environments. Test whether the product is resistant to high and low temperatures.

The salt spray test chamber can test the salt spray corrosion ability of the material and its protective layer, as well as the process quality comparison of similar protective layers, and can test the salt spray corrosion resistance of some products.

CONTACT US

Take advantage of our unrivaled knowledge and experience, we offer you the best customization service.

Get catalog now

Just leave your email or phone number on the contact form so we can provide you with more services!

Recommended

Copyright © 2022 BOTTLE - aivideo8.com All Rights Reserved.