Plastic is indispensable in our daily life, so, do you know how plastic products are produced? Today, let's take a look at how our products are injection molded.

Injection molding, also known as injection molding, is a molding method of injection and molding. The advantages of the injection molding method are that the production speed is fast, the efficiency is high, the operation can be automated, there are many varieties of colors, the shape can be from simple to complex, the size can be from large to small, and the size of the product is accurate, the product is easy to replace, and it can be formed into complex shapes. Parts, injection molding is suitable for mass production and complex shape products and other molding processing fields. At a certain temperature, the completely molten plastic material is stirred by a screw, injected into the mold cavity with high pressure, and cooled and solidified to obtain a molded product. This method is suitable for mass production of complex-shaped parts, and is one of the important processing methods.

Get catalog now

Just leave your email or phone number on the contact form so we can provide you with more services!

Recommended

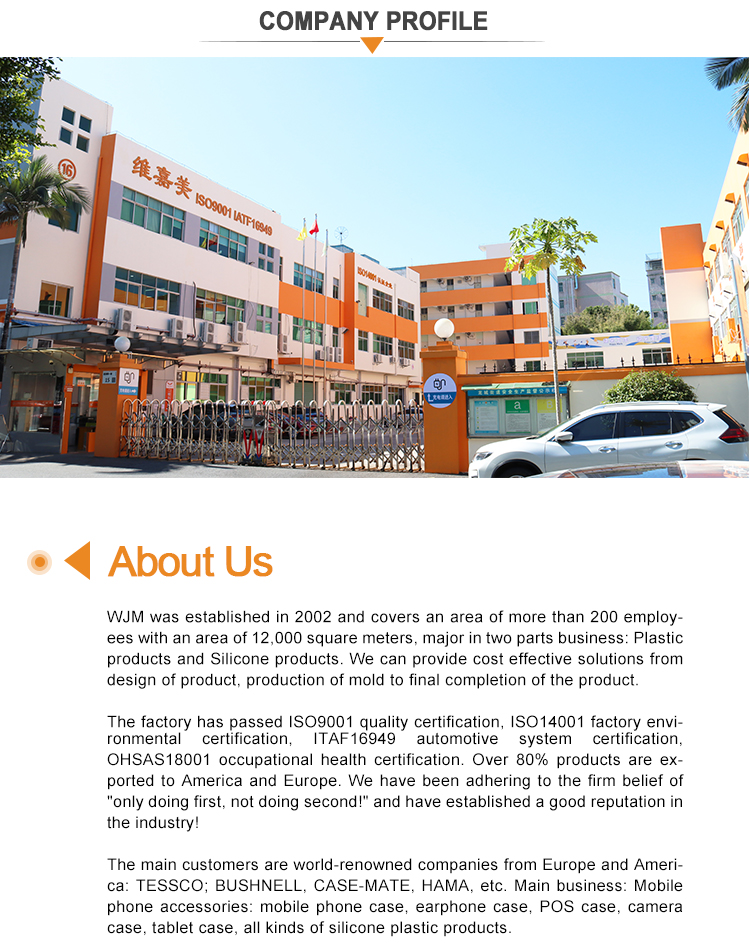

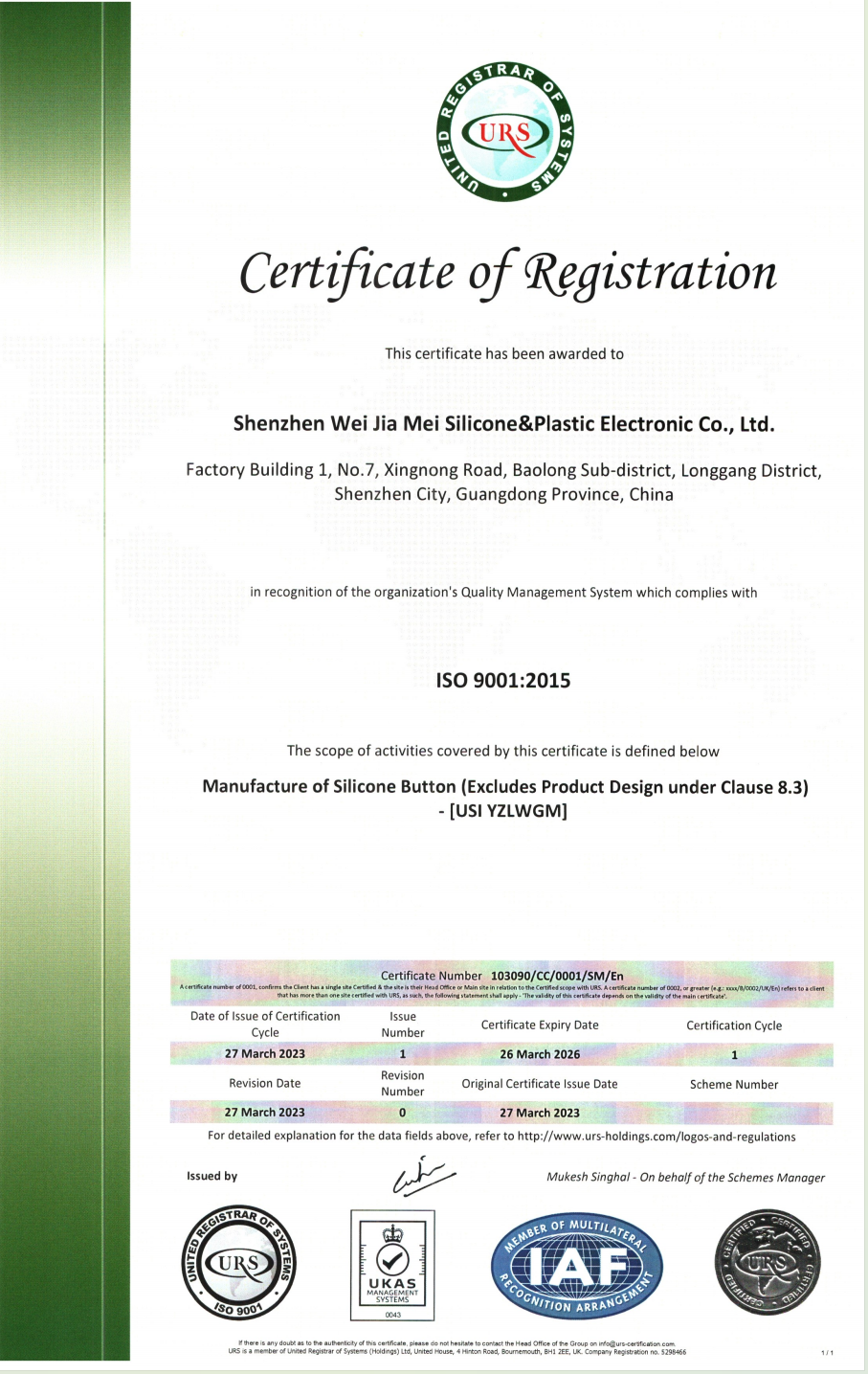

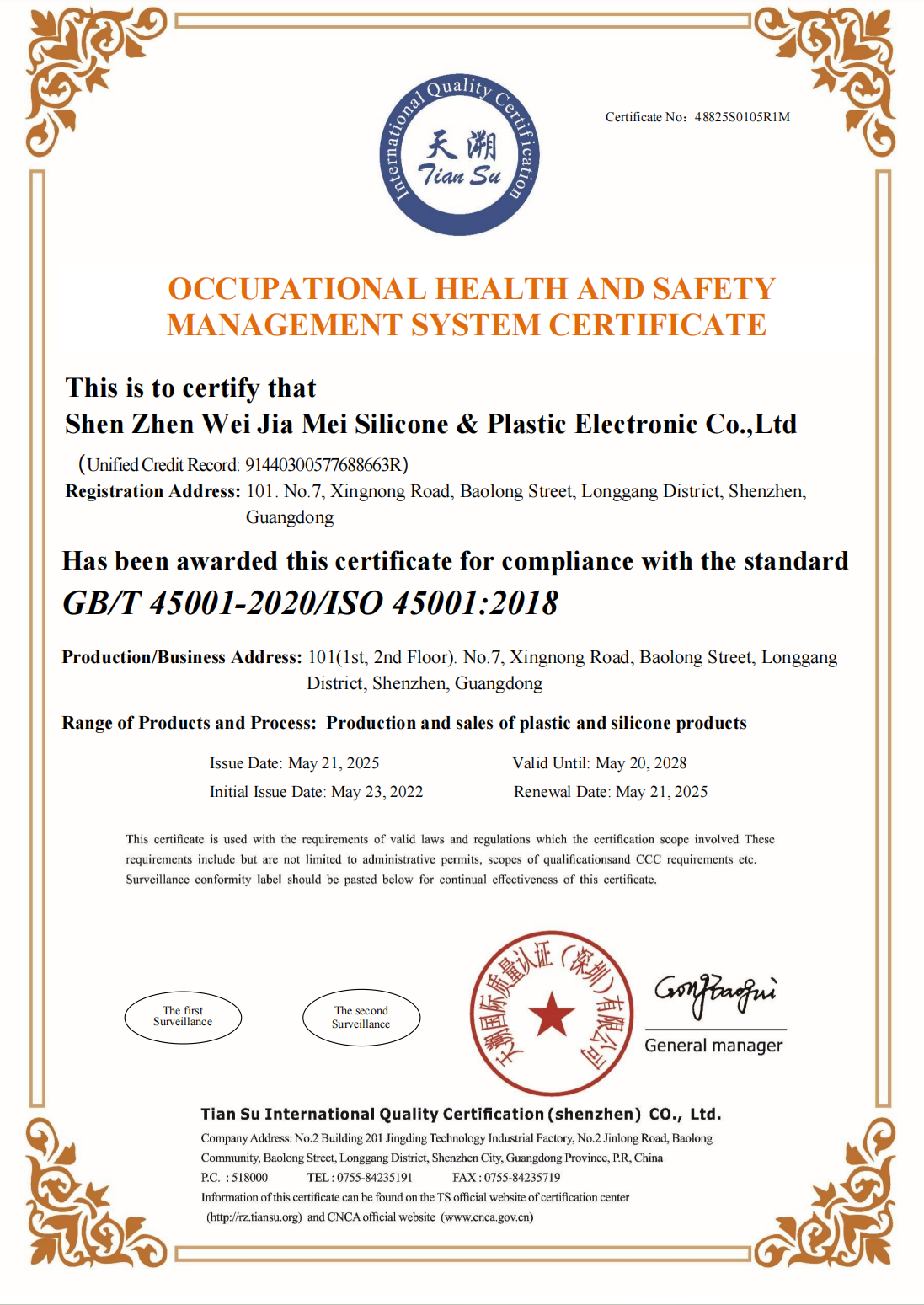

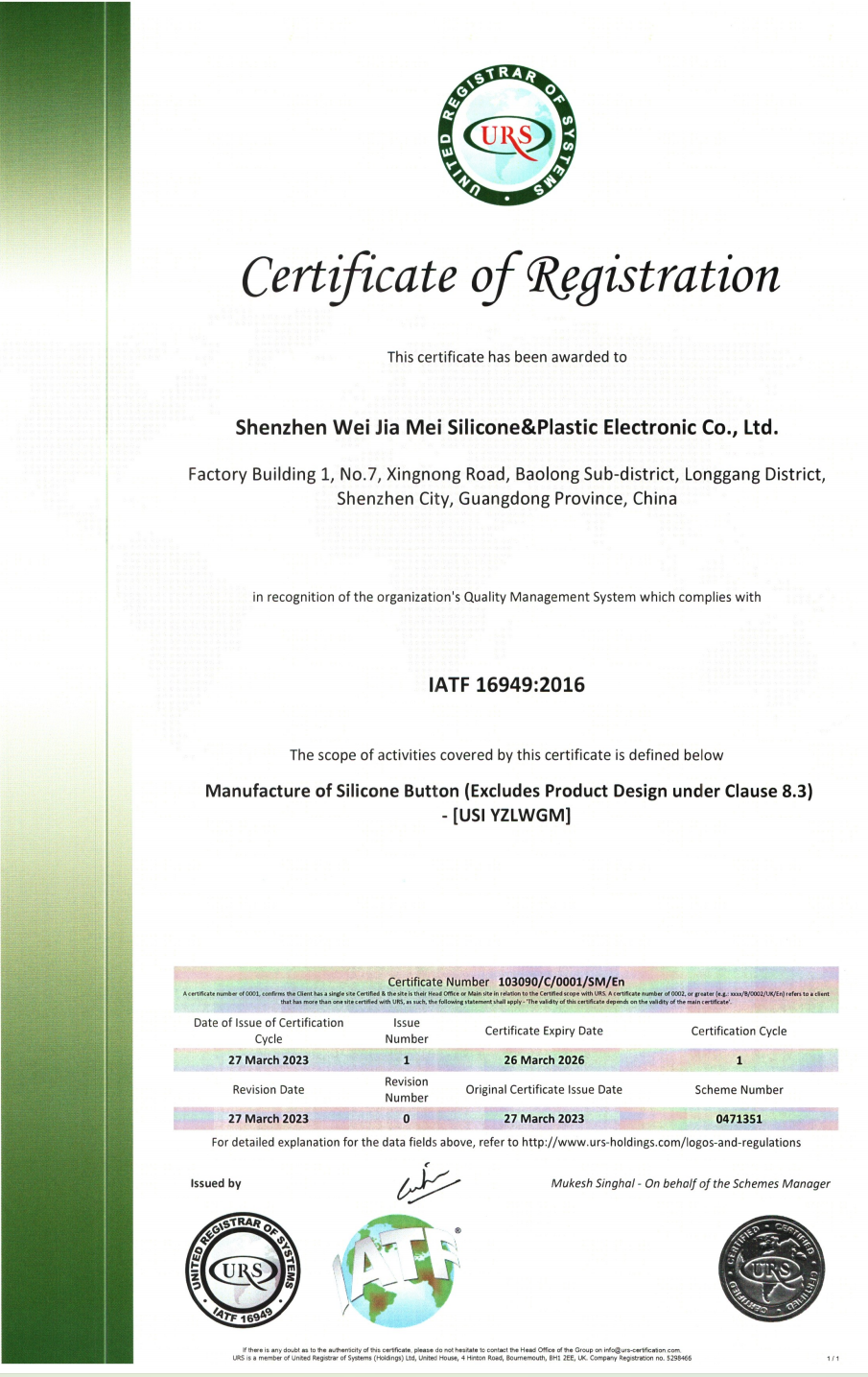

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.

Copyright © 2022 BOTTLE - aivideo8.com All Rights Reserved.