With strong R&D strength and production capabilities, WJM now has become a professional manufacturer and reliable supplier in the industry. All our products including injection molding accessories are manufactured based on the strict quality management system and international standards. injection molding accessories Having devoted a lot to product development and service quality improvement, we have established a high reputation in the markets. We promise to provide every customer throughout the world with prompt and professional service covering the pre-sales, sales, and after-sales services. No matter where you are or what business you are engaged in, we'd love to help you deal with any issue. If you want to know more details about our new product injection molding accessories or our company, feel free to contact us.WJM is the outcome of the crystallization of human wisdom. It is developed adopting the knowledge of ergonomics with the combination of the features of different mobile phones.

Transform your projector with our custom-made plastic shell! Our expertly-crafted accessory is not only stunning in appearance but also effortless to install. Enjoy the convenience and functionality of this incredible product with most projectors on the market. Don't settle for anything less than perfection – personalize your projector shell to suit your unique style and needs. Get ready to be amazed by the possibilities that await you! Contact us today for an unforgettable experience.

We customize silicone protective cases for mobile devices. We make protective covers for projectors, medical equipment, massagers, electronic cigarettes, stereos, power banks, POS machines, and various other products in need.

High-quality silicone can well protect your machine from wind, sun, dust and the risk of breaking.

We have a professional team to serve you. You only need to provide your ideas, and we can realize this project. We have engineering designers to develop and design products for you, and then make molds and produce products. We provide you with everything from R&D to For all delivery services, we have professional quality inspectors, and unqualified products will never come to your hands.

We have more than 8,000 customized cases, and the factory has more than 9,000 molds. We are also a silicone and plastic factory, with a daily production capacity of more than 15,000 pieces/

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhen WJM Silicone&Plastic Electronic Co., Ltd., most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality OEM Silicone Cases and an unforgettable experience of partnering with us.

The buyers of injection molding accessories come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

Regarding the attributes and functionality of the injection molding accessories, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Shenzhen WJM Silicone&Plastic Electronic Co., Ltd. always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

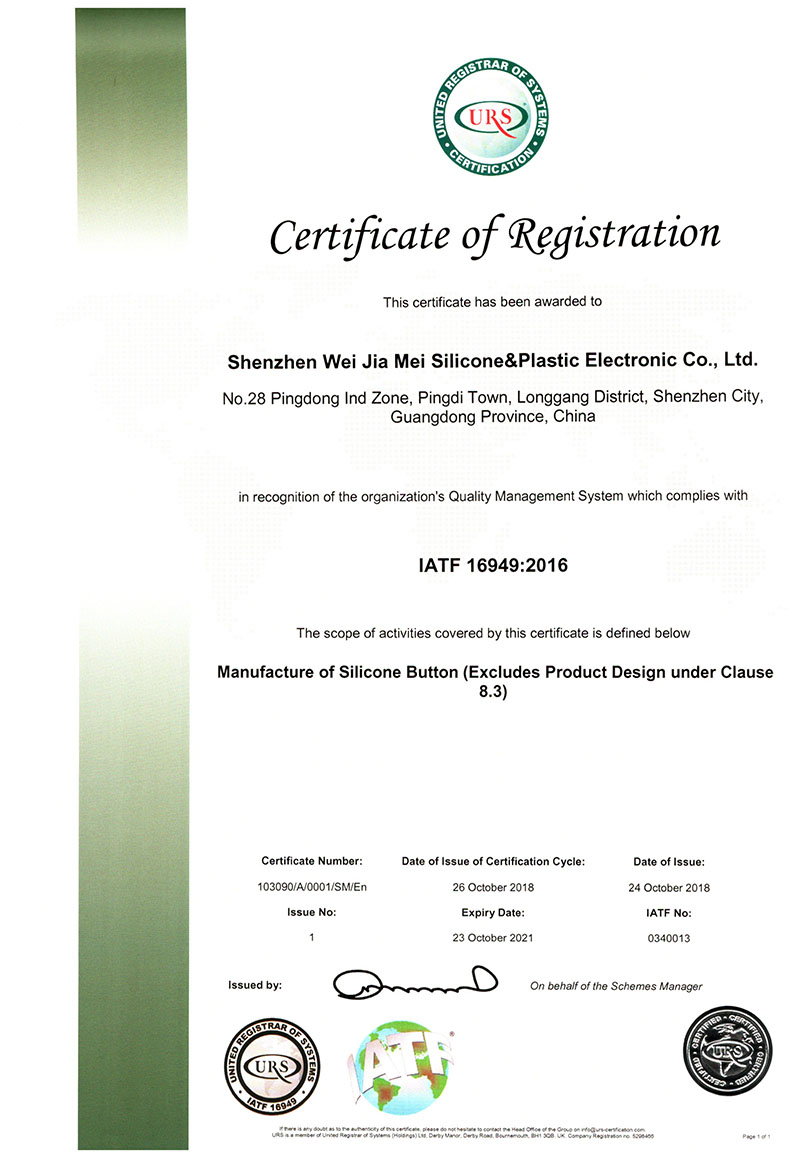

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. injection molding accessories QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Copyright © 2022 BOTTLE - aivideo8.com All Rights Reserved.