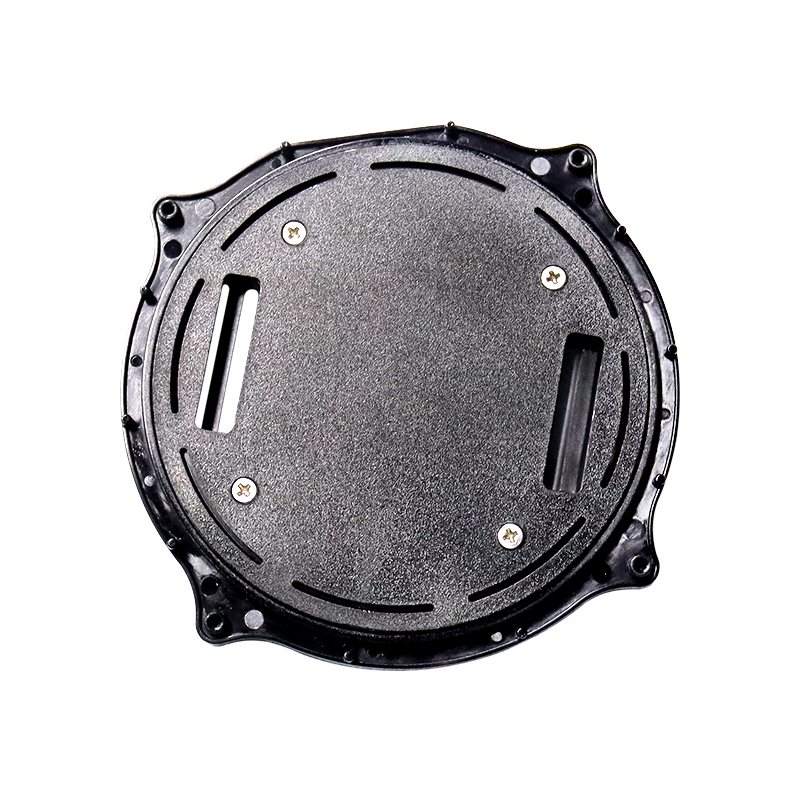

Relying on advanced technology, excellent production capabilities, and perfect service, WJM takes the lead in the industry now and spreads our WJM all over the world. Together with our products, our services are also supplied to be the highest-level. injection molding accessories If you are interested in our new product injection molding accessories and others, welcome you to contact us.The quality of WJM injection molding accessories is guaranteed. It is sent to the designated testing acceptance center for phone accessories to check its overall quality.

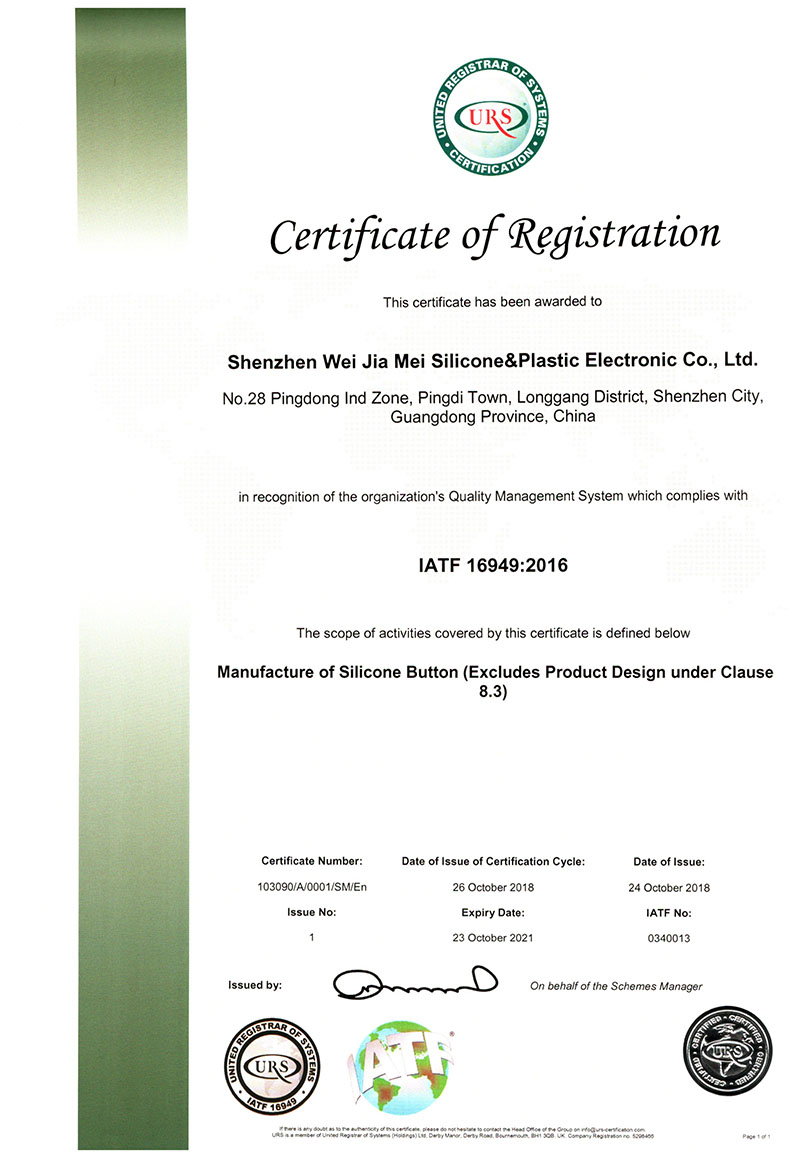

For plastic products, we generally do accessories and the like. We have dozens of injection molding machines and professionals. Every year, we design and produce a large number of customized plastic products which are exported both domestically and abroad. Our workshop has passed the test of the certificate, and the quality can be well guaranteed. Our company has ten years of experience in injection molding and has produced more than 12,000 sets of molds. If you need to bring 3D drawings or sample designs, we have a professional design team to design for you, and place an order for production after confirmation.

For plastic products, we generally make accessories and the like. We have dozens of injection molding machines and professional staff. Every year, a large number of customized plastic products are designed and produced to be sold at home and abroad. Our workshops have passed the test of the certificate, and the quality can be well guaranteed. Our company has ten years of experience in injection molding and has produced more than 12,000 sets of molds. If you need to bring 3D drawings or samples to design, we have a professional design team to design for you, and only after confirmation will you place an order for production.

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhen WJM Silicone&Plastic Electronic Co., Ltd., most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality OEM Silicone Cases and an unforgettable experience of partnering with us.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Regarding the attributes and functionality of the injection molding accessories, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Yes, if asked, we will supply relevant technical details regarding WJM. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. injection molding accessories QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Regarding the attributes and functionality of the injection molding accessories, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Copyright © 2022 BOTTLE - aivideo8.com All Rights Reserved.