With strong R&D strength and production capabilities, WJM now has become a professional manufacturer and reliable supplier in the industry. All our products including plastic part design are manufactured based on the strict quality management system and international standards. plastic part design We have professional employees who have years of experience in the industry. It is them that provides high-quality services for customers all over the world. If you have any questions about our new product plastic part design or want to know more about our company, feel free to contact us. Our professionals would love to help you at any time.This product is absolutely a smart accessory to the mobile phone owners, for the fact that it greatly helps increase convenience.

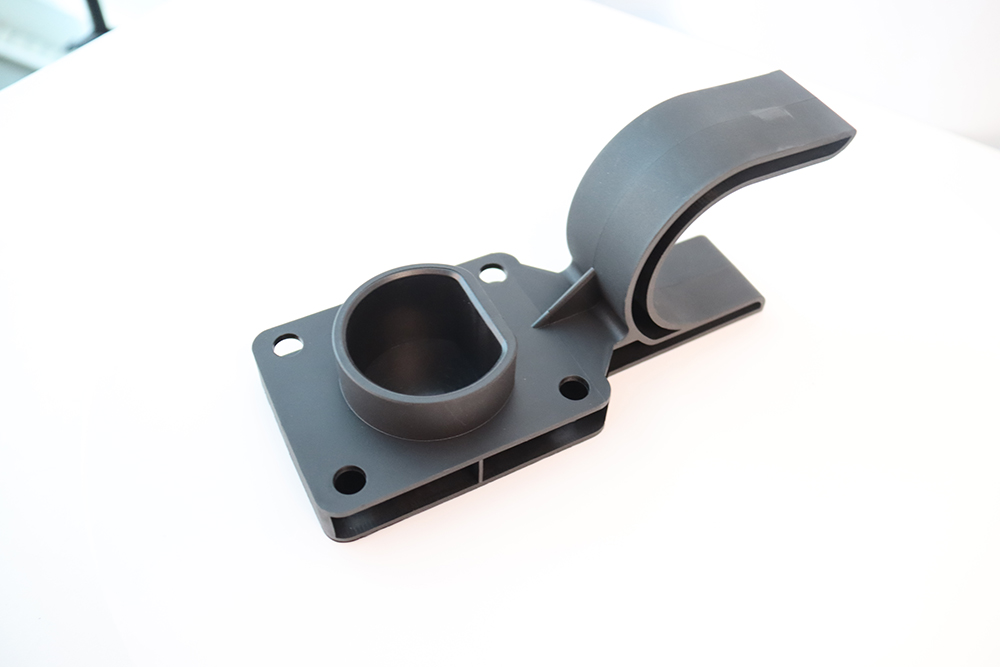

Factory Custom Car Charging Pile Accessories

Factory Custom Car Charging Pile Accessories,We customize all kinds of new energy vehicle charging pile plastics, and we can also customize other plastic accessories for you, such as beauty instrument shells, remote control shells, electric vehicle accessories and various plastic products.

We have a professional team to serve you. You only need to provide your ideas, and we can realize this project. We have engineering designers to develop and design products for you, and then make molds and produce products. We provide you with everything from R&D to For all delivery services, we have professional quality inspectors, and unqualified products will never come to your hands.

We have more than 8,000 customized cases, and the factory has more than 9,000 molds. We are also a silicone and plastic factory, with a daily production capacity of more than 15,000 pieces/

In essence, a long-standing plastic part design organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

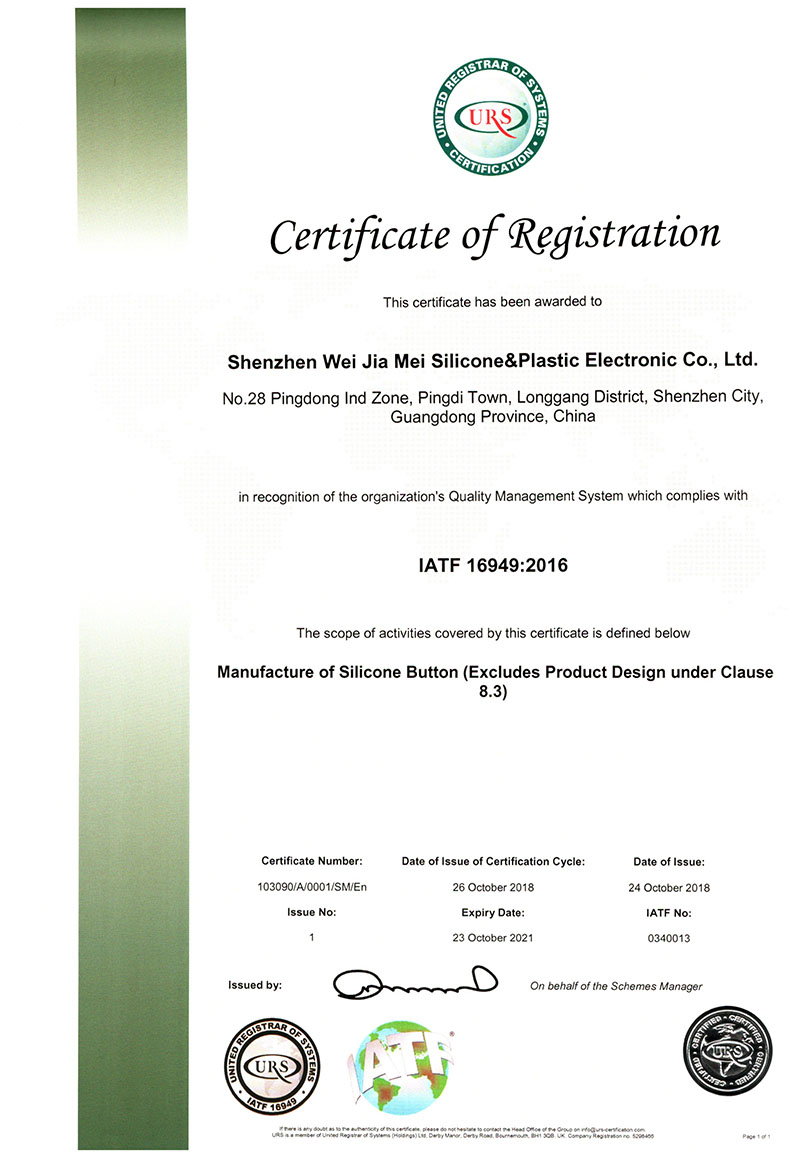

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. plastic part design QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Regarding the attributes and functionality of the plastic part design, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

The buyers of plastic part design come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

Yes, if asked, we will supply relevant technical details regarding WJM. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhen WJM Silicone&Plastic Electronic Co., Ltd., most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality OEM Plastic Cases and an unforgettable experience of partnering with us.

Copyright © 2022 BOTTLE - aivideo8.com All Rights Reserved.