This customized scanner plastic shell cover is an essential injection molding machine accessory designed to protect and encase scanners for optimal performance and durability. With a focus on precise engineering and quality materials, this product ensures a perfect fit and long-lasting protection for your equipment. The customizable design options and professional service provided by our experienced team make this product a reliable choice for all your injection molding machine accessory needs.

Our company is a leading manufacturer of Injection Molding Machine Accessories, specializing in customized Scanner Plastic Shell Covers. With a focus on quality and precision, we utilize state-of-the-art injection molding technology to create durable and high-performance products tailored to fit your specific needs. Our team of experts is dedicated to delivering exceptional products that meet the highest industry standards, ensuring reliability and innovation in every aspect. From concept to completion, we strive to exceed customer expectations and provide solutions that enhance efficiency and productivity. Trust us to be your partner in enhancing your injection molding operations with our top-of-the-line accessories.

Founded in [year], our company specializes in providing high-quality injection molding machine accessories, including customized scanner plastic shell covers. With a focus on innovation and precision, we create products that meet the specific needs of our clients. Our team of experts combines cutting-edge technology with years of experience to deliver top-notch solutions. Customer satisfaction is our top priority, and we strive to exceed expectations with every order. Trust us to provide you with durable, efficient, and reliable products that will enhance the performance of your machinery. Choose us for all your injection molding machine accessory needs.

Customized instrument Scanner Body Plastic Shell Cover

We customize various instrument accessories, such as scanners, remote controls, charging piles, beauty instruments, and various auto accessories, etc.Our engineering designers have thirty years of experience and can provide you with the best service. For more questions, please contact us and we will reply you within 24 hours.

We have a professional team to serve you. You only need to provide your ideas, and we can realize this project. We have engineering designers to develop and design products for you, and then make molds and produce products. We provide you with everything from R&D to For all delivery services, we have professional quality inspectors, and unqualified products will never come to your hands.

We have more than 8,000 customized cases, and the factory has more than 9,000 molds. We are also a silicone and plastic factory, with a daily production capacity of more than 15,000 pieces/

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhen WJM Silicone&Plastic Electronic Co., Ltd., most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Pos cases and an unforgettable experience of partnering with us.

Regarding the attributes and functionality of the injection molding machine accessories, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

In essence, a long-standing injection molding machine accessories organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Regarding the attributes and functionality of the injection molding machine accessories, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

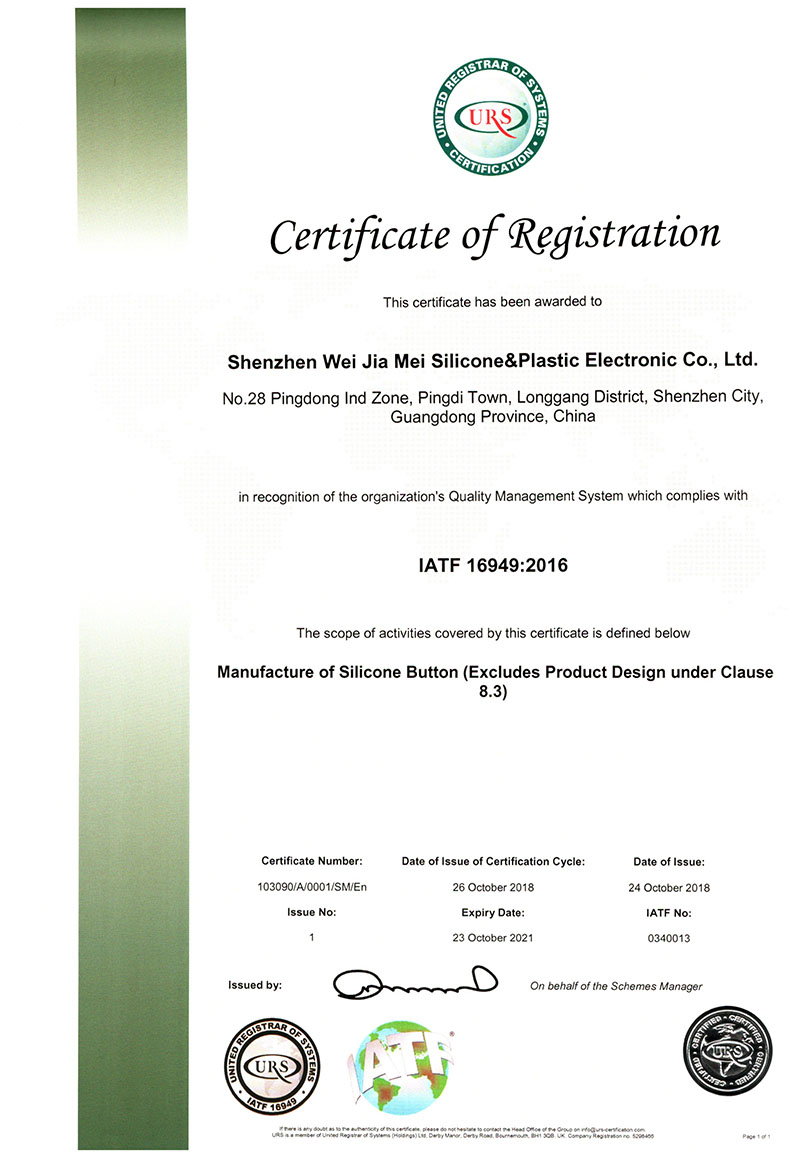

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. injection molding machine accessories QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Copyright © 2022 BOTTLE - aivideo8.com All Rights Reserved.