Our customized plastic parts manufacturing service offers a wide range of options for instrument accessories such as scanners, remote controls, charging piles, beauty instruments, and auto accessories. With thirty years of experience, our engineering designers can bring your ideas to life and provide top-notch service from R&D to delivery. Benefit from our extensive mold library of over 9,000 molds and daily production capacity exceeding 15,000 pieces, ensuring eco-friendly and durable products at competitive prices.

At Customized Plastic Parts Manufacturing, our team strength lies in our unmatched expertise and dedication to delivering high-quality, customized plastic parts. Our team of experienced engineers and designers collaborate seamlessly to bring your vision to life, ensuring precise manufacturing and timely delivery. With a strong focus on innovation and continuous improvement, we are able to exceed industry standards and provide cost-effective solutions for all your plastic part needs. Trust in our team's commitment to excellence and let us help you achieve success in your projects. Experience the power of our team strength at Customized Plastic Parts Manufacturing.

Our specialized team of engineers and technicians sets us apart in the customized plastic parts manufacturing industry. With years of experience and expertise, our team excels in creating high-quality, precise parts that meet and exceed our customers' expectations. From design to production, our team works closely together to ensure every part is made to perfection. We prioritize communication and collaboration, allowing us to efficiently problem solve and deliver top-notch products on time. Trust in our team's strength to provide you with reliable, customized plastic parts that will elevate your project to the next level.

Customized instrument Scanner Body Plastic Shell Cover

We customize various instrument accessories, such as scanners, remote controls, charging piles, beauty instruments, and various auto accessories, etc.Our engineering designers have thirty years of experience and can provide you with the best service. For more questions, please contact us and we will reply you within 24 hours.

We have a professional team to serve you. You only need to provide your ideas, and we can realize this project. We have engineering designers to develop and design products for you, and then make molds and produce products. We provide you with everything from R&D to For all delivery services, we have professional quality inspectors, and unqualified products will never come to your hands.

We have more than 8,000 customized cases, and the factory has more than 9,000 molds. We are also a silicone and plastic factory, with a daily production capacity of more than 15,000 pieces/

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhen WJM Silicone&Plastic Electronic Co., Ltd., most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Silicone Product and an unforgettable experience of partnering with us.

Regarding the attributes and functionality of the plastic parts manufacturing, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Regarding the attributes and functionality of the plastic parts manufacturing, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

The buyers of plastic parts manufacturing come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

Yes, if asked, we will supply relevant technical details regarding WJM. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

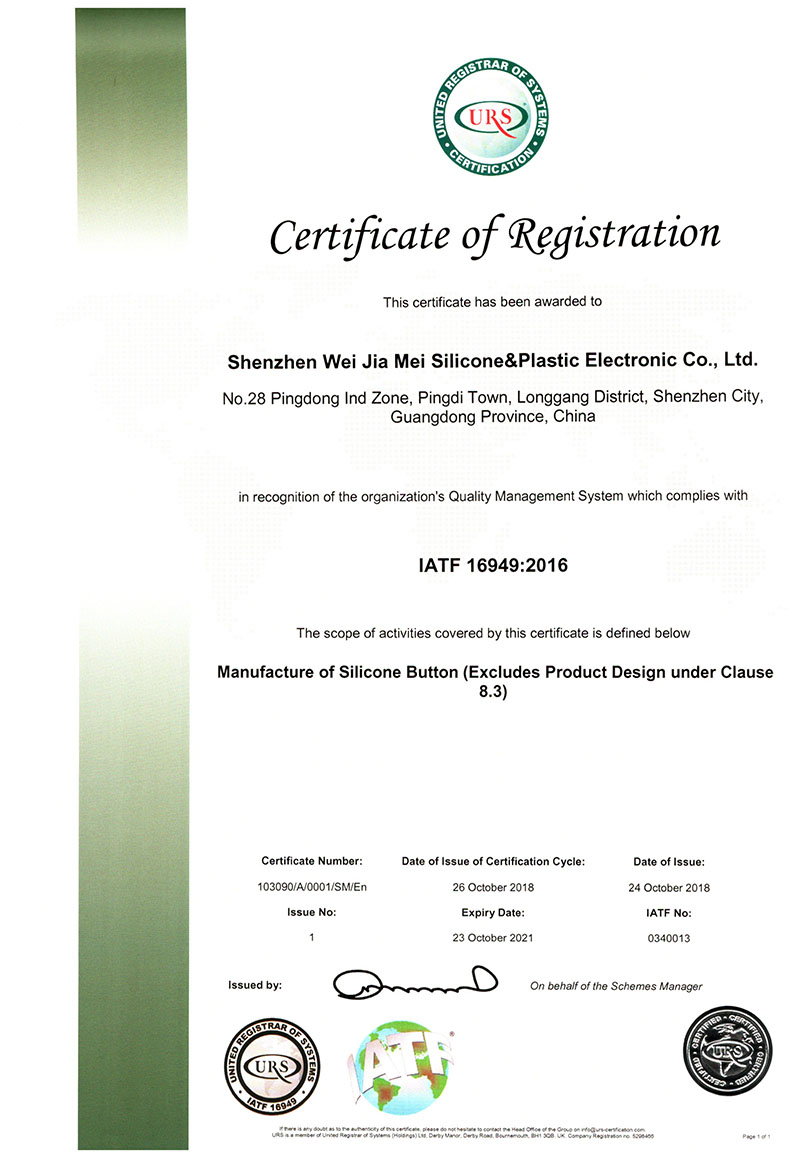

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. plastic parts manufacturing QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Copyright © 2022 BOTTLE - aivideo8.com All Rights Reserved.