Our custom silicone protective cases are high quality and designed to fit perfectly with your mobile devices, projectors, medical equipment and more. Made with durable materials, these customized enclosures provide protection from wind, sun, dust, and potential damage. With over 8,000 custom cases and 9,000 molds available, our plastic injection mold parts are ideal for any product in need of personalized protection.

When it comes to protecting your device, our team strength lies in our ability to provide high-quality custom enclosures that are made from durable silicone material. Our team of experts works tirelessly to ensure that each case is customized to fit your device perfectly, offering maximum protection from everyday wear and tear. With our attention to detail and commitment to quality, you can trust that your device is in safe hands. Additionally, our team's dedication to customer satisfaction means that we are always available to address any concerns or questions you may have, ensuring a smooth and stress-free experience.

Enhance your team's strength with our custom silicone protective cases. Our high-quality customized enclosures offer superior protection and personalization for your electronic devices. With a strong team behind our product development and customer service, we ensure every case is made to perfection and meets your specific needs. Our attention to detail and dedication to customer satisfaction sets us apart in the industry. Choose our custom cases to not only protect your devices but also to showcase your team's strength and unity. Strengthen your brand identity with our custom silicone protective cases today.

We customize silicone protective cases for mobile devices.We make protective covers for projectors, medical equipment, massagers, electronic cigarettes, stereos, power banks, POS machines, and various other products in need.

High-quality silicone can well protect your machine from wind, sun, dust and the risk of breaking.

We have a professional team to serve you. You only need to provide your ideas, and we can realize this project. We have engineering designers to develop and design products for you, and then make molds and produce products. We provide you with everything from R&D to For all delivery services, we have professional quality inspectors, and unqualified products will never come to your hands.

We have more than 8,000 customized cases, and the factory has more than 9,000 molds. We are also a silicone and plastic factory, with a daily production capacity of more than 15,000 pieces/

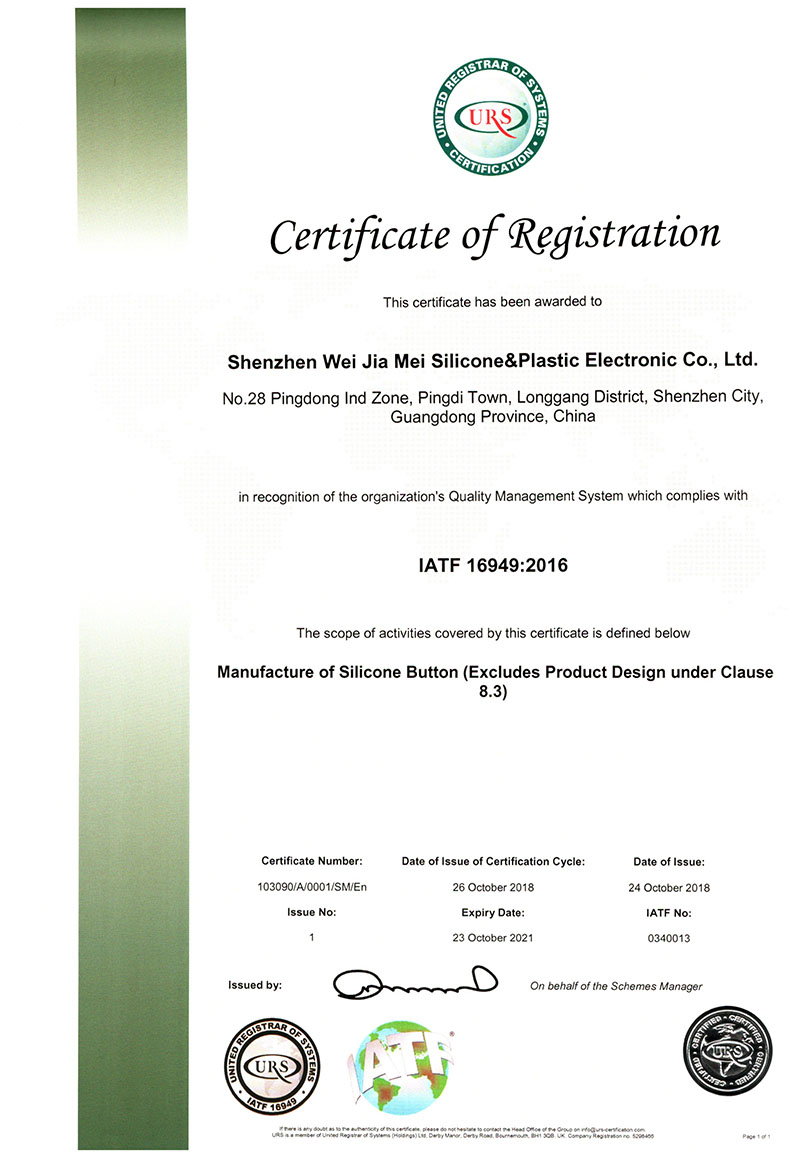

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. plastic injection mold parts QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

In essence, a long-standing plastic injection mold parts organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Shenzhen WJM Silicone&Plastic Electronic Co., Ltd. always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

The buyers of plastic injection mold parts come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhen WJM Silicone&Plastic Electronic Co., Ltd., most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality OEM Tablet Cover and an unforgettable experience of partnering with us.

Copyright © 2022 BOTTLE - aivideo8.com All Rights Reserved.