Product features

Our custom plastic injection mold parts are designed to meet any material and any design specifications you may have, ensuring high quality and durability. With over ten years of experience in injection molding and more than 12,000 sets of molds produced, we guarantee top-notch products. Our workshop is certified and equipped with advanced facilities, allowing us to provide one-stop service production for your plastic parts needs.

Team strength

Team strength is at the heart of our custom plastic parts manufacturing process. With our dedicated team of skilled engineers and designers, we are able to create top-quality parts from our own molds. Our team's expertise allows us to work with any material and bring any design to life, ensuring that our customers receive exactly what they need. We prioritize collaboration and communication within our team, allowing us to work seamlessly together to deliver exceptional results. Trust in our team's strength and experience to provide you with the perfect custom plastic parts for your project.

Enterprise core strength

Team Strength:

Our team of skilled professionals is dedicated to providing top-quality custom plastic parts created from our own molds. With expertise in a wide range of materials and designs, we can bring your vision to life with precision and efficiency. Our cohesive team collaborates seamlessly to ensure each product meets the highest standards of craftsmanship and durability. From initial concept to final production, our team’s collective knowledge and experience guarantee a seamless process and exceptional results. Trust in our team’s strength to deliver superior custom plastic parts that exceed your expectations.

Product Introduction

For plastic products, we generally do accessories and the like. We have dozens of injection molding machines and professionals. Every year, we design and produce a large number of customized plastic products that are sold at home and abroad. Our workshop has passed the test of the certificate, and the quality can be well guaranteed. Our company has ten years of experience in injection molding and has produced more than 12,000 sets of molds. If you need to bring 3D drawings or sample designs, we have a professional design team to design for you, and place an order for production after confirmation

Product Information

Company Advantages

Multi stocked samples are available.

Committed to producing the best quality products at the most competitive prices. One-stop service production

Eco-friendly and durable raw material, multi-dimensional protective the mobile devices

Certifications and Patents

Frequently Asked Questions about wholesale silicone case

Q:Do you support free sample?

A:Yes, we support free sample for stock, 3-7 workdays to reach you

Q:1. Why choose WJM custom case?

A:We have 20 years experience in silicone and 10 years in plastic, including silicone and plastic assembly, mainly for custom products

Q:12.How about the OEM service flow?

A:Compared to ODM, OEM customization has a shorter process. As an independent OEM service provider, WJM promises a smooth OEM service offering process. It begins with detailed and thorough communication between both parties, in which the needs for the products should all be confirmed. After that, the sample will be delivered to customers for confirmation. Then, based on the needs, the project will be formulated reasonably for offering the greatest interests to customers. The whole process can be very cost-saving due to our familiarity and expertise with the products.

Q:9.Does WJM provide OEM service?

A:Yes, we do. With the fast expansion of the company, WJM has developed several businesses and service ranges including OEM service to satisfy the growing needs of customers throughout the whole world. Based on customers' needs, we are required to manufacture the products only and don't need to design or develop new products. We are equipped with advanced facilities that ensure the high precision and perfect fit for each part. Several production lines are installed to ensure the high-efficiency production process, which ensures that any order, no matter how many the order quantity is, can be completed on time.

Q:7. Quantity (MOQ)

A:The minimum size of our POS machine case is 200pcs, the earphone case and mobile phone case are 500pcs, and other products should be estimated according to the actual product.

FAQ

1.Do your products reach the Europe, North America or Japan quality standard?

Yes, our products are compliant with SGS, MSDS and CE certificates. so we definitely can meet your market standard

2.What kind of Payment method do you accept?

We accept Paypal or Alibaba Payment for Sample orders. T/T Westem Union, Alibaba Payment for mass orders

3.Do you support free sample?

Yes, we support free sample for stock, 3-7 workdays to reach you

Advantages

1.Eco-friendly and durable raw material, multi-dimensional protective the mobile devices

2.mobile phone accessories silicone plastic products and auto parts supply series, established in 2002 and covers an area of 12,000 square meters with more than 200 employees.

3.Multi stocked samples are available.

4.The factory has passed ISO9001 quality certification, ISO14001 factory environmental certification

About WJM

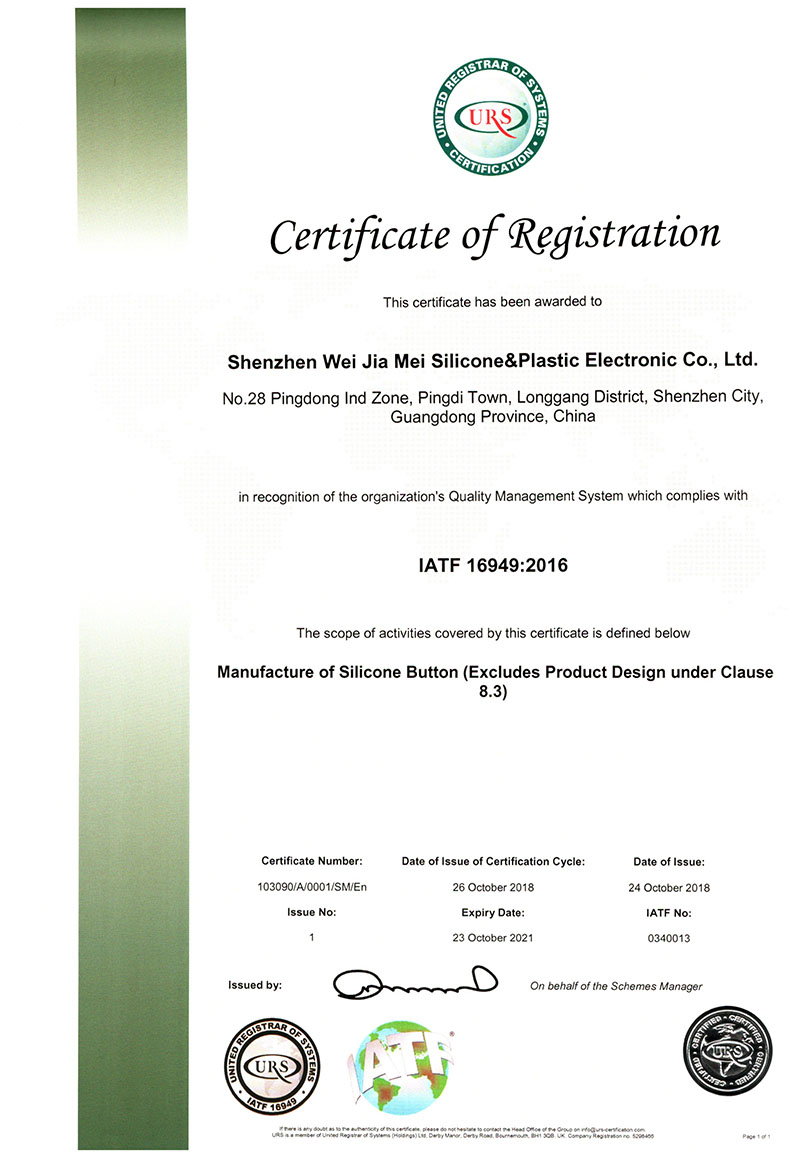

Shenzhen WJM Silicone & Plastic Electronic Co., Ltd. is located in Ailian Zhangbei Industrial Zone, Longgang District, Shenzhen. The main business has two major sectors, mobile phone accessories silicone plastic products and auto parts supply series, Weijiamei was established in 2002, covers an area of 12,000 square meters with more than 200 employees. The factory has passed ISO9001 quality certification, ISO14001 factory environmental certification,

ITAF16949 automotive system certification, OHSAS18001 occupational health certification. We have been adhering to the firm belief of "only doing first, not doing second!" and have established a good reputation in the industry! We have strong engineering research and development capabilities and product production capabilities, such as precision injection molding workshop, silicone product workshop, precision mold workshop, auto parts production workshop, modern quality packaging production line.

At the same time, a group of enterprise management personnel, engineering and technical personnel and on-site operators with rich industry experience were brought together. The main customers are world-renowned companies from Europe and America: TESSCO; BUSHNELL, CASE-MATE, HAMA, etc. Main business: Mobile phone accessories: mobile phone case, tablet case, POS case, camera case, all kinds of silicone plastic products.

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhen WJM Silicone&Plastic Electronic Co., Ltd., most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Pos cases and an unforgettable experience of partnering with us.

Yes, if asked, we will supply relevant technical details regarding WJM. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Shenzhen WJM Silicone&Plastic Electronic Co., Ltd. always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

Regarding the attributes and functionality of the plastic injection mold parts, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

The buyers of plastic injection mold parts come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.