Product features

Our custom plastic injection parts offer high quality and are fully customizable to meet your specific needs. With a team of professionals and advanced injection molding machines, we have the capability to design and produce a wide range of customized plastic products that are sold both domestically and abroad. Our workshop is certified for quality assurance, ensuring that every product meets the highest standards in the industry.

We serve

At XYZ Company, we take pride in serving our customers with custom plastic injection parts of the highest quality. Our team of expert engineers and designers work tirelessly to provide custom solutions to meet your unique needs. With a focus on precision and attention to detail, we ensure that each part meets the highest standards of quality and craftsmanship. From concept to production, we are dedicated to delivering exceptional service and exceeding your expectations. Whether you need a prototype or a large production run, we are here to serve you every step of the way. Experience the difference with XYZ Company.

Why choose us

When it comes to custom plastic injection parts, our company takes pride in offering high-quality products with the option for customization. At our core, we serve our customers by providing durable and precise parts that meet their specific needs. From concept to production, we are dedicated to delivering exceptional service and ensuring satisfaction every step of the way. Our value lies in our ability to collaborate with clients to bring their unique visions to life, offering flexibility and creativity in our manufacturing process. Trust us to serve you with top-notch custom plastic injection parts that exceed expectations.

product description

For plastic products, we generally do accessories and the like. We have dozens of injection molding machines and professionals. Every year, we design and produce a large number of customized plastic products, which are sold domestically and abroad. Our workshop has passed the test of the certificate, and the quality can be well guaranteed. Our company has ten years of experience in injection molding and has produced more than 12,000 sets of molds. If you need to bring 3D drawings or sample designs, we have a professional design team to design for you, and place an order for production after confirmation.

product information

company advantage

A variety of stock samples are available.

Committed to producing the highest quality products at the most competitive prices. One-stop service production

Environmentally friendly and durable raw materials, multi-dimensional protection of mobile devices

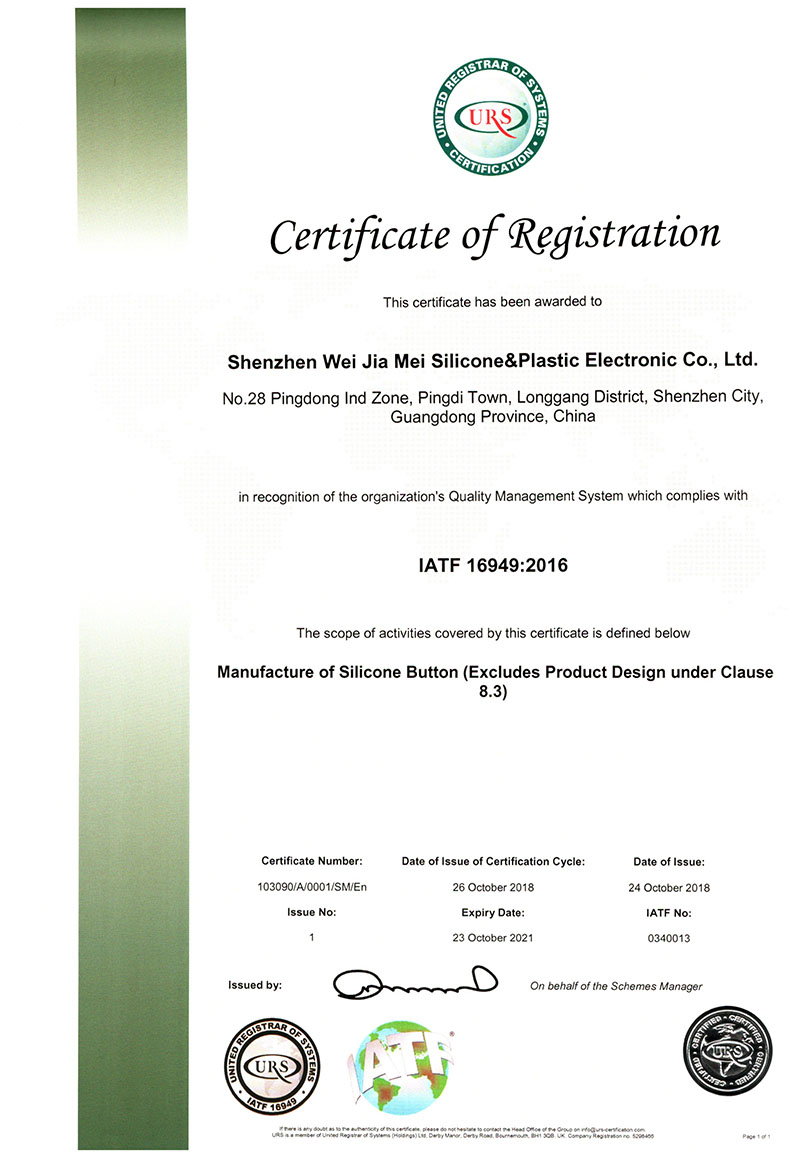

Certifications and Patents

Frequently Asked Questions about Wholesale Silicone Covers

ask:Do you support free samples?

A:Yes, we support free sample stock, 3-7 working days to deliver to you

ask:1. Why choose WJM custom case?

A:We have 20 years experience in silicone and 10 years in plastic, including silicone and plastic assembly, mainly for custom products

ask:12.How about the OEM service process?

A:Compared with ODM, OEM customization process is shorter. As an independent OEM service provider, WJM is committed to providing a smooth OEM service delivery process. It starts with a detailed and thorough communication between both parties, in which the need for the product should be confirmed. After that, the samples will be delivered to the customer for confirmation. Then, according to the needs, the project is rationally formulated to provide the maximum benefit to the client. The entire process can be very cost-effective due to our familiarity and expertise with the product.

ask:9. Does WJM provide OEM service?

A:Yes, we have. With the rapid expansion of the company, WJM has developed a number of business and service lines including OEM services to meet the growing needs of customers around the world. According to the needs of customers, we only need to manufacture products, no need to design or develop new products. We are equipped with advanced facilities to ensure high precision and perfect fit of each part. Multiple production lines are installed to ensure the high efficiency of the production process, ensuring that any order, regardless of the order quantity, can be completed on time.

ask:7. Quantity (MOQ)

A:The minimum size of our POS machine case is 200pcs, the earphone case and mobile phone case are 500pcs, and other products are estimated based on actual products.

FAQ

1. How do you ship the goods?

We ship by air and sea by express (DHL, UPS, FedEX, TNT)

2. Do you support free samples?

Yes, we support free sample stock, 3-7 working days to deliver to you

3. What payment methods do you accept?

We accept Paypal or Alibaba payment for sample order. T/T Western Union, Alibaba bulk order payment

advantage

1. The factory has passed ISO9001 quality certification and ISO14001 factory environment certification

2. Mobile phone accessories silicone products and auto parts supply series, established in 2002, covers an area of 12,000 square meters and employs more than 200 people.

3. Production capacity: 18 years of experience. More than 200 employees. 12,000m³ workshop

4. Environmentally friendly and durable raw materials, multi-dimensional protection of mobile devices

About WJM

Shenzhen WJM Silicone& Plastic Electronics Co., Ltd. is located in Zhangbei Industrial Zone, Ailian, Longgang District, Shenzhen. The main business includes two major sectors: mobile phone accessories silicone products and auto parts supply series. Weijiamei was established in 2002, covers an area of 12,000 square meters and has more than 200 employees. The factory has passed ISO9001 quality certification, ISO14001 factory environment certification,

ITAF16949 automotive system certification, OHSAS18001 occupational health certification. We have been adhering to the firm belief of "only be the first, not the second"! And established a good reputation in the industry! We have strong engineering R&D capabilities and product production capabilities, such as precision injection molding workshops, silicone product workshops, precision mold workshops, auto parts production workshops, and modern quality packaging production lines.

At the same time, a group of industry-experienced enterprise managers, engineering technicians and field operators have been gathered. The main customers are world-renowned companies in Europe and America: TESSCO; BUSHNELL, CASE-MATE, HAMA, etc. Main business: Mobile phone accessories: mobile phone cases, tablet computer cases, POS cases, camera cases, various silicone plastic products.