Our custom plastic injection moulding accessories are designed and produced by our experienced professionals using top-quality materials. With our workshop passing certification tests, you can trust in the high quality of our products. Whether you need customized plastic accessories for domestic or international markets, we have the expertise and capability to fulfill your requirements.

At Custom Plastic Injection Moulding Accessories, our team strength is the backbone of our success. With a diverse group of experts in design, engineering, and production, we are able to deliver high-quality, customized products to meet our customers' specific needs. Our team's unparalleled commitment to excellence and innovation sets us apart in the industry, ensuring that every product we produce is of the highest standard. By leveraging our collective expertise and collaborative approach, we are able to consistently exceed expectations and provide exceptional value to our customers. Trust in our team strength to deliver the perfect solution for all your injection moulding accessory needs.

At Custom Plastic Injection Moulding Accessories, our team strength lies in our collective expertise and commitment to delivering top-notch products. With a group of skilled engineers and designers, we ensure that each accessory is precisely crafted to meet the highest standards of quality. Our team's dedication to innovation and problem-solving enables us to fulfill custom orders with efficiency and precision. From concept to production, our team works seamlessly together to turn ideas into reality, providing customers with reliable and durable accessories for all their moulding needs. Trust in our team strength to deliver excellence every time.

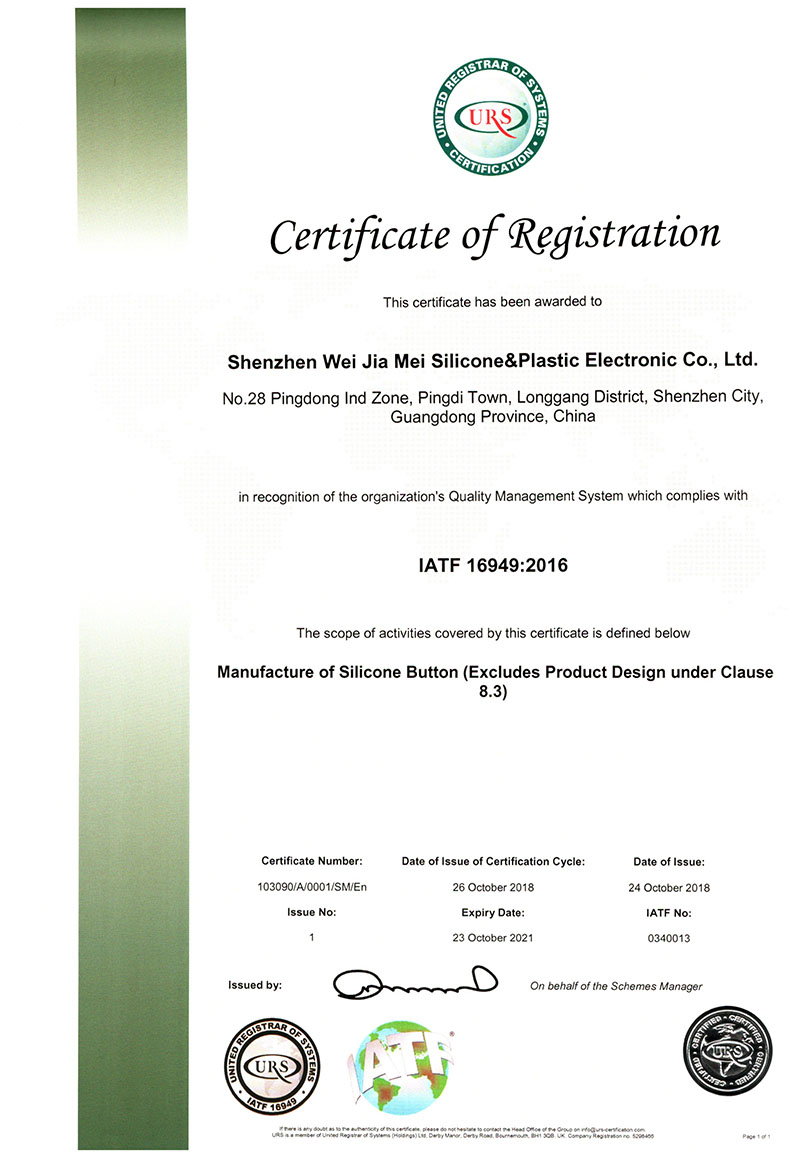

For plastic products, we generally do accessories and the like. We have dozens of injection molding machines and professionals. Every year, we design and produce a large number of customized plastic products which are exported both domestically and abroad. Our workshop has passed the test of the certificate, and the quality can be well guaranteed. Our company has ten years of experience in injection molding and has produced more than 12,000 sets of molds. If you need to bring 3D drawings or sample designs, we have a professional design team to design for you, and place an order for production after confirmation.

Copyright © 2022 BOTTLE - aivideo8.com All Rights Reserved.