WJM's custom plastic injection mold parts provide high precision and consistency in production, ensuring reliable performance for various industries. With advanced manufacturing technology and experienced engineers, WJM delivers customized solutions to meet specific design requirements and production needs. The products are cost-effective, durable, and versatile, making them a preferred choice for companies looking to optimize their manufacturing processes.

WJM is a leading manufacturer of custom plastic injection mold parts, providing high-quality solutions for a wide range of industries. With a focus on precision engineering and innovative design, our experienced team delivers reliable and cost-effective products that meet the unique needs of our customers. Our commitment to exceptional quality, fast turnaround times, and competitive pricing sets us apart in the market. Whether you need prototypes or high-volume production runs, WJM has the expertise and capabilities to ensure your project is a success. Trust us for all your plastic injection mold part needs and experience the difference our company can make.

WJM is a leading manufacturer of custom plastic injection mold parts, specializing in high-quality and precision components for various industries. With years of experience and expertise in injection molding technology, we offer personalized solutions to meet our clients' specific requirements. Our state-of-the-art facility and skilled team ensure top-notch product quality and timely delivery. We prioritize customer satisfaction and strive for continuous improvement in our processes to provide cost-effective and efficient solutions. Trust WJM for all your custom plastic injection mold part needs and experience excellence in every detail.

Introducing our custom plastic molding parts and protective cases for accessories, designed to provide a high level of protection and functionality for your electronic devices and accessories. We use advanced manufacturing techniques to create custom-molded plastic parts and cases that perfectly fit your devices, ensuring maximum protection and durability.

WJM custom molding parts and protective cases are available in a wide range of designs, colors, and finishes, allowing you to create a customized look that matches your brand or personal style. We offer a variety of materials to choose from, including ABS, polycarbonate, and other high-quality plastics that are both lightweight and strong.

Whether you need custom-molded plastic parts for a specific device or a protective case for your accessories, WJM can provide a solution that meets your needs. Our team of experienced engineers and designers will work closely with you to understand your requirements and develop a custom solution that fits your unique specifications.

At our WJM plastic cases company, we are committed to providing the highest level of quality and customer service. We use only the best materials and manufacturing techniques to ensure that our products meet the highest standards of quality and durability. Contact us today to learn more about our custom plastic molding parts and protective cases for accessories, and let us help you protect your electronic devices and accessories with style.

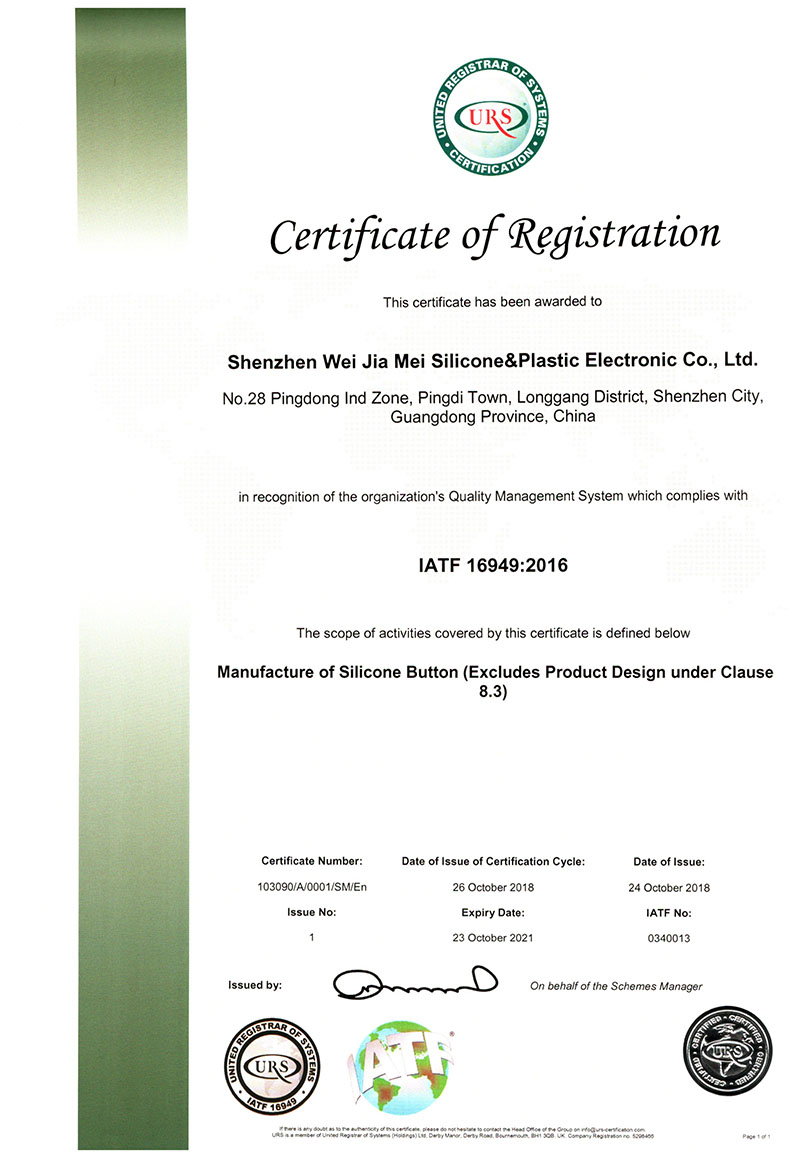

For plastic products, we generally do accessories and the like. We have dozens of injection molding machines and professionals. Every year, we design and produce a large number of customized plastic products that are exported both domestically and abroad. Our workshop has passed the test of the certificate, and the quality can be well guaranteed. Our company has ten years of experience in injection molding and has produced more than 12,000 sets of molds. If you need to bring 3D drawings or sample designs, we have a professional design team to design for you and place an order for production after confirmation.

Regarding the attributes and functionality of the plastic injection mold parts, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

In essence, a long-standing plastic injection mold parts organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Shenzhen WJM Silicone&Plastic Electronic Co., Ltd. always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

The buyers of plastic injection mold parts come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Yes, if asked, we will supply relevant technical details regarding WJM. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

Copyright © 2022 BOTTLE - aivideo8.com All Rights Reserved.